Automatic Door Motors precisely manage speed and direction. They use various motor types, advanced speed technologies, and smart control units. These units interpret sensor inputs and execute programmed movements. The global automatic door market grows approximately 7% annually, highlighting their widespread use. Understanding how does an automatic door motor work reveals complex engineering. Different types of automatic door motors serve diverse applications. For instance, an automatic door motor for hospital environments requires high reliability. Such Automatic Door Motors ensure smooth access. When an automatic door not opening occurs, it often points to a control system or sensor issue.

Key Takeaways

- Automatic doors use different motors and smart control units to move doors precisely.

- Sensors act like eyes and ears for automatic doors, telling them when to open or stop.

- Control units use special programming to decide how fast and in what direction the door should move.

- Safety features like obstacle detection and emergency stops keep people safe around automatic doors.

- Automatic doors can change their speed to fit different situations, like busy times or bad weather.

Core Components for Precise Automatic Door Motors Control

Motor Types Driving Door Movement

Automatic doors rely on specific motor types for their operation. Each motor offers distinct advantages. DC motors, which run on direct current, provide high torque and energy efficiency. They are common in residential sliding doors and smaller commercial setups. AC motors use alternating current. They are durable and cost-effective for long-term use. Shopping malls and airports often use AC motors. Stepper motors rotate in exact steps. This allows for precise control without needing a feedback system. Clean rooms or laboratories use these motors. Synchronous motors operate in sync with the power supply. They offer constant speed and high reliability. Revolving doors in hotels often feature synchronous motors. For example, the YF200 Automatic sliding door motor is a 24V brushless DC motor. It has a rated power of 100W. This motor works well for heavy-duty sliding door operators, ensuring quiet, stable, strong, and safe movement.

Gear Systems for Mechanical Advantage

Motors alone sometimes lack the power to move heavy doors smoothly. Gear systems provide a mechanical advantage. They connect to the motor and change its speed and torque. Gears reduce the motor’s speed while increasing the force it can apply. This allows a smaller motor to move a large, heavy door. Gear motors are ideal for low-speed, high-torque tasks. They suit automatic doors and overhead doors well. These systems provide the necessary force to open doors efficiently.

Sensors Guiding Door Operations

Sensors act as the eyes and ears of automatic doors. They detect people or objects and tell the door what to do. Infrared motion sensors are common. They detect movement by sending out infrared beams. Pressure sensors detect physical contact or weight. They often appear as pads on the floor. Optical sensors use light to detect things. They measure changes in light or analyze laser reflections. Radar movement sensors use radar technology. They detect movement, including direction, and can see through some obstacles. Other sensors include proximity sensors, which detect presence without movement, and photoelectric sensors, which use a light beam across an area.

The Brains Behind Automatic Door Motors Movement: Control Units

Microprocessors Interpreting Signals

Microprocessors serve as the central processing unit for automatic doors. They receive and process all incoming data. Sensors send signals to the microprocessor. These signals tell the system about detected movement, obstacles, or door position. The microprocessor quickly analyzes this information. It then makes decisions about the door’s next action. For example, if a motion sensor detects a person, the microprocessor decides to open the door. This rapid interpretation ensures the door responds correctly and safely to its environment.

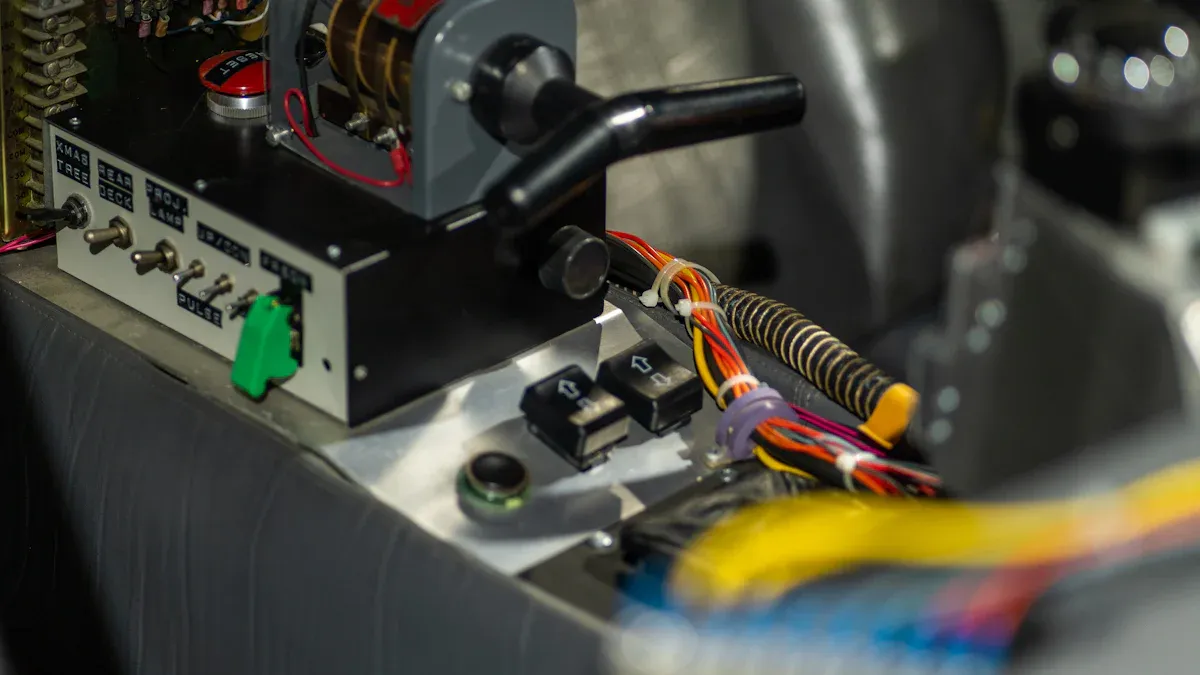

Programming Logic for Door Behavior

Automatic doors follow specific rules for their operation. These rules are part of the door’s programming logic. This logic dictates how the door behaves under different conditions. It determines opening and closing speeds, hold-open times, and safety responses. Engineers often use a ladder diagram programming language to create this logic. This visual language helps define the sequence of operations. It ensures the door performs its functions reliably. The programming logic makes sure the door opens when someone approaches and closes safely afterward.

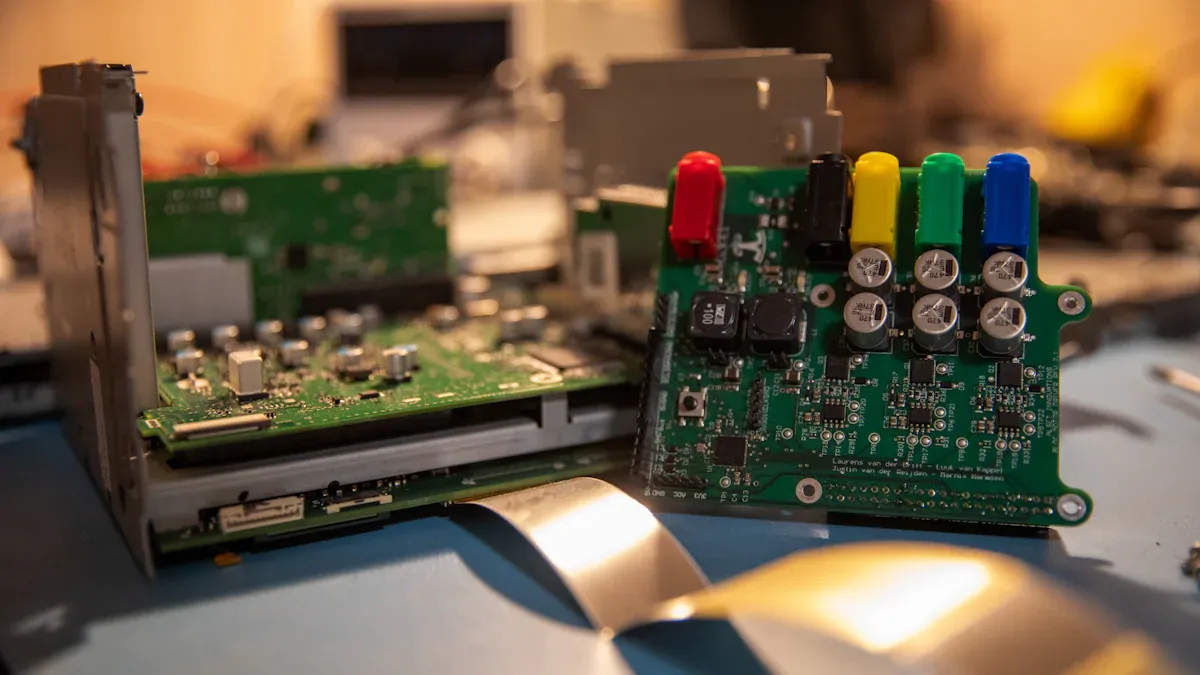

Communication with Motor Drivers

The control unit needs to tell the motor what to do. It communicates these commands to the motor drivers. Motor drivers are electronic circuits that control the motor’s power. They translate the control unit’s digital signals into electrical currents that move the motor. Integrated servo motors, common in Automatic Door Motors, often use specific communication methods. These include fieldbus or industrial Ethernet protocols. Examples are CANopen, EtherCAT, Modbus, or PROFINET. The CAN protocol is also widely used in building automation, including automatic doors. These protocols allow seamless and efficient data exchange. They ensure the motor receives precise instructions for speed and direction.

Achieving Precision: Speed and Direction Control Mechanisms for Automatic Door Motors

Automatic doors require precise control over their speed and direction. This precision ensures smooth operation, safety, and efficiency. Various technologies make this possible, adapting to different motor types and operational needs.

Variable Frequency Drives for AC Motors

Variable Frequency Drives (VFDs) are essential for controlling AC motors in automatic door systems. VFDs adjust the frequency and voltage of the electrical power supplied to the motor. This allows them to precisely regulate the motor’s speed and torque.

VFDs offer several key advantages for AC motors in automatic doors:

- Adjustable Torque Limit: VFDs allow precise control over the torque an AC motor applies. This prevents damage to machinery and products. For instance, if an automatic door encounters an obstruction, the VFD limits the motor’s torque. This prevents excessive force.

- Controlled Stopping: VFDs enable smooth, ramped deceleration. This reduces mechanical stress and wear on the door’s components. It extends their lifespan.

- Energy Savings: VFDs can significantly reduce energy consumption. They do this in applications where the motor does not always need to run at full speed. Precise speed control during opening and closing cycles leads to energy efficiencies.

- Reverse Operation: VFDs provide electronic reversing capabilities. This eliminates the need for separate reversing starters. It simplifies the control system for automatic doors. It also reduces maintenance and saves panel space.

- Elimination of Mechanical Drive Components: VFDs offer infinitely variable speed control. This can potentially remove the need for gearboxes or other speed-altering mechanical components. This leads to lower maintenance costs and a more compact design.

These benefits make VFDs a crucial component for modern AC-powered automatic doors. They ensure reliable and efficient performance.

Pulse Width Modulation for DC Motors

Pulse Width Modulation (PWM) is a common technique for controlling the speed of DC motors. PWM works by rapidly switching the power supply to the motor on and off. It does this many times per second.

PWM controls motor speed by regulating the voltage across its terminals.

- PWM operates by driving the motor with a series of ‘ON-OFF’ pulses.

- Motor speed varies by adjusting the ‘duty cycle.’ This is the fraction of time the output voltage is ‘ON’ compared to ‘OFF.’ The frequency remains constant.

- Varying the width of these applied pulses changes the average DC voltage supplied to the motor terminals.

- A longer ‘ON’ pulse (wider pulse width) results in a higher average voltage. This creates a stronger magnetic flux and faster motor rotation.

- A shorter ‘ON’ pulse leads to a lower average voltage and slower motor rotation.

PWM adjusts the average voltage delivered to a DC motor. This controls its speed without excessive electrical noise. The ‘duty cycle’ determines the average power and voltage supplied. High duty cycles provide more power, increasing motor speed. Low duty cycles decrease power and reduce speed. This method is highly efficient. It has minimal power loss during switching. PWM is widely used in automation, including Automatic Door Motors, where precise motor control is essential.

Encoder Feedback for Positional Accuracy

Encoders provide crucial feedback to the control unit. They measure the exact position, speed, and direction of the door. This feedback loop ensures the door moves precisely as intended. Encoders translate mechanical motion into electrical signals. The control unit then interprets these signals.

Various types of encoders ensure positional accuracy in automatic door systems:

- EH 17 – EH 30: These are incremental optical kit encoders. They provide pulses for each increment of movement.

- EA 36: This is an absolute magnetic singleturn solid shaft encoder. It provides a unique position value for each shaft angle.

- EAM 36 F/G: This is an absolute magnetic multiturn blind hollow shaft encoder. It tracks multiple rotations and provides an absolute position.

- EM – ER 38: This is an incremental optical blind hollow shaft encoder. It offers incremental feedback for hollow shaft applications.

Absolute encoders are particularly useful in automatic door systems. They enable movement without the need for limitation switches. This simplifies installation and improves reliability. Encoders ensure the door opens to the correct width and stops exactly where it should. They also detect any deviations from the programmed path. This allows the system to make immediate corrections.

Integrated Safety and Adaptive Features of Automatic Door Motors

Automatic doors do more than just open and close. They include smart safety features and adapt to different situations. These features protect people and ensure smooth operation.

Obstacle Detection and Reversal

Automatic doors actively look for anything in their path. Sensors along the door’s edges or on the floor scan for obstructions. If the system detects an object or person, the door stops. It will either stay open or re-open if it started to close.

Several types of sensors help with this:

- Anti-pinch photoelectric sensors (photo eyes): These create an infrared light path across the door opening. If something blocks this path, the sensor detects it. This stops the door from closing.

- Infrared (IR) Sensors: They send out infrared beams. The door halts when something breaks the beam.

- Microwave Sensors: These emit continuous microwave signals. The door stops or reverses when reflected signals show an object.

- Ultrasonic Sensors: They use sound waves. These sensors send out pulses and measure the time it takes for the sound to return. This detects objects nearby.

- Contact Sensors: Pressure-sensitive mats or strips are often at the door’s bottom. The door stops or reverses when pressure is applied.

- Safety Edges: These are flexible strips on door panels. They signal the door to stop or reverse when an obstacle compresses them.

Advanced control systems combine data from many sensors. They use smart programs to make real-time decisions. This improves safety and reduces mistakes. When anti-pinch sensors detect an obstruction, the system triggers an immediate stop and reversal. This reaction happens very fast, often in less than 50 milliseconds.

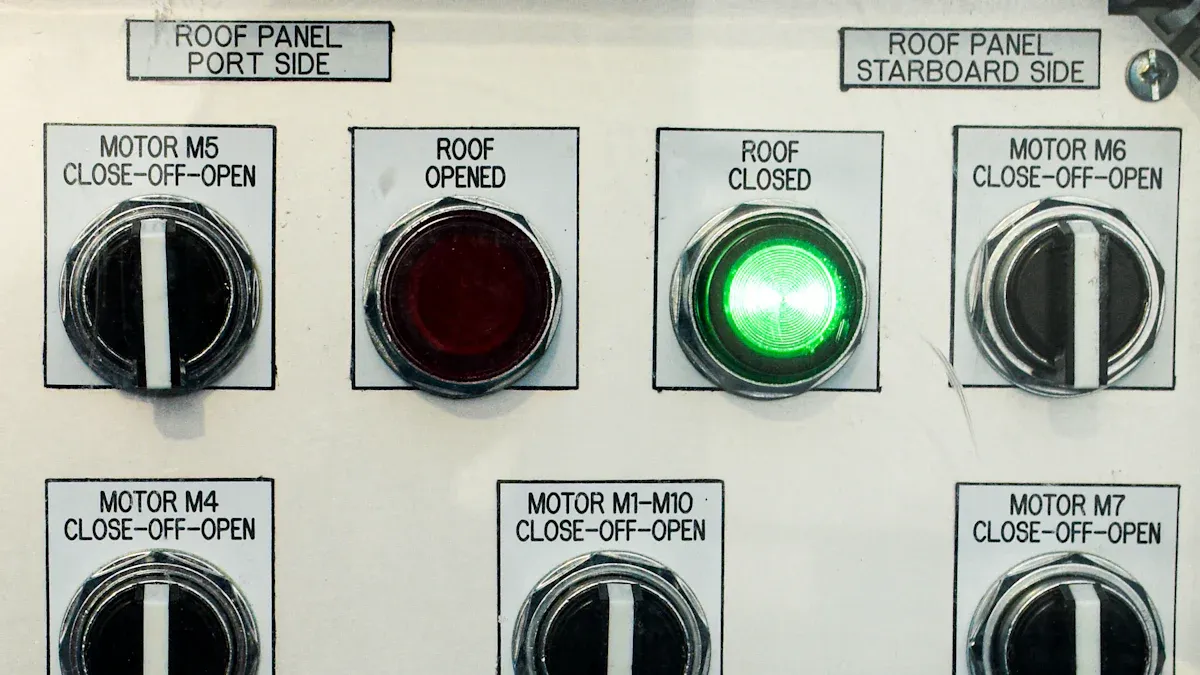

Emergency Stop Protocols

Automatic doors also have emergency stop protocols. These are critical safety measures. They allow the door to stop immediately in an emergency. People can activate these protocols manually, often with a clearly marked button. The system can also trigger them if it detects a major malfunction. This ensures safety for everyone near the door.

Adaptive Speed for Different Conditions

Automatic doors can change their speed. They adapt to different conditions. For example, during busy times, a door might open and close faster. This helps manage heavy foot traffic. In quieter periods, the door might move slower. This saves energy and reduces wear. Weather conditions can also affect speed. A door might open slower in strong winds to prevent damage. Sensors provide information about these conditions. The control unit then adjusts the door’s speed for optimal performance and safety.

Automatic Door Motors achieve precise speed and direction control. They integrate motor technology, advanced control units, and real-time feedback. Variable speed technologies and intelligent programming ensure efficient operation and user safety. This clever engineering allows automatic doors to adapt to various environments and user needs. They provide reliable and controlled access for everyone.

FAQ

How does an automatic door motor know when to open?

Automatic door motors use sensors. These sensors detect movement or presence. When a person approaches, the sensor sends a signal. The control unit then tells the motor to open the door.

What is the difference between AC and DC motors in automatic doors?

AC motors use alternating current. They are durable and good for heavy use. DC motors use direct current. They offer high torque and energy efficiency, often for smaller doors.

Why do automatic doors sometimes reverse direction?

Automatic doors reverse for safety. Sensors detect obstacles in the door’s path. If an object is present, the door stops closing. It then re-opens to prevent pinching or injury.

Can automatic door motors save energy?

Yes, many automatic door motors save energy. Variable Frequency Drives (VFDs) for AC motors and Pulse Width Modulation (PWM) for DC motors optimize speed. This reduces power consumption when the door does not need full speed.

What role do encoders play in automatic door operation?

Encoders provide precise feedback. They measure the door’s exact position and speed. This information helps the control unit ensure the door opens and closes accurately. It also maintains safety.