This guide identifies top-tier Chinese brands for automatic door motors designed for commercial electric sliding doors. It highlights their exceptional performance, durability, and value. Many inquire, “Which reliable automatic door motors supplier in China is good?” We explore leading manufacturers like Ningbo Beifan Automatic Door Factory. This resource helps you navigate the market and select reliable suppliers, including insights into China’s top 5 automatic door motors suppliers. Discover the ideal automatic electric door opener for your specific requirements.

This guide identifies top-tier Chinese brands for automatic door motors designed for commercial electric sliding doors. It highlights their exceptional performance, durability, and value. Many inquire, “Which reliable automatic door motors supplier in China is good?” We explore leading manufacturers like Ningbo Beifan Automatic Door Factory. This resource helps you navigate the market and select reliable suppliers, including insights into China’s top 5 automatic door motors suppliers. Discover the ideal automatic electric door opener for your specific requirements.

Key Takeaways

- Chinese automatic door motors offer good quality at a lower cost. They use new technology and have many options for different places like hotels or offices.

- Top Chinese brands like KBB, Olide, and Ningbo Beifan make reliable automatic door motors. They have good reputations and important safety approvals.

- When choosing a motor, check its power for your door’s weight. Also, look for safety features like sensors and make sure the company offers good support after you buy.

- Always check for quality certificates like ISO 9001 and CE. Read what other customers say and make sure the supplier has good shipping experience.

Why Choose Chinese Automatic Door Motors for Sliding Doors?

Cost-Effectiveness and Quality

Chinese manufacturers offer a compelling combination of cost-effectiveness and quality for automatic door motors. They provide high-performance solutions at competitive prices. This allows businesses and individuals to access advanced automation technology without significant financial outlay. Manufacturers maintain rigorous quality control standards, ensuring product reliability and longevity. This balance makes Chinese automatic door motors a smart investment for various projects.

Advanced Technology and Innovation in Automatic Door Motors

Chinese manufacturers consistently push the boundaries of innovation in automatic door motors. They integrate advanced technological features into their products. For example, many systems now include Smart Ready features. These offer interfaces for airbags, light curtains, infrared sensors, vehicle proximity detection, and mobile remote opening. Manufacturers also develop new AC&DC Electronic limit rolling door motors. They independently create intelligent door and gate motors with comprehensive automation system solutions. Furthermore, DC automatic door opener motors are available in various voltages, such as 12V, 24V, 36V, and 48V, catering to diverse application needs. The integration of worm planetary gearbox encoders further enhances precision and control.

Diverse Options for Various Applications

Chinese automatic door motor suppliers offer a wide array of options suitable for numerous applications. Their products serve a broad spectrum of environments. These include hotels, clubs, office buildings, and various exhibition halls. Specialized solutions also exist for clean rooms, laboratories, and precision-based environments, often utilizing stepper motors. Hotels and corporate buildings frequently employ their motors for revolving doors. Manufacturers also provide solutions for residential front doors and large commercial entrances. This extensive range ensures customers find the perfect motor for their specific requirements.

Global Accessibility and Supply Chain

Chinese manufacturers have established a robust global presence. They export products to over 60 countries and regions worldwide. This extensive network ensures wide availability of their automatic door systems. Key markets include America, Australia, and Europe. Specific examples of their reach extend to Porto, Kenya, Casablanca, and Argentina. Many suppliers serve more than 25 countries, demonstrating their extensive international network.

This global accessibility offers significant advantages to buyers. It simplifies the procurement process for businesses and individuals across different continents. Manufacturers have developed efficient supply chains. These chains ensure timely delivery and consistent product availability. Buyers can source high-quality components regardless of their geographical location. This widespread distribution also fosters competitive pricing. It allows more businesses to access advanced door automation solutions.

The well-developed supply chain infrastructure supports this global reach. Chinese factories often have large production capacities. They can meet high demand from various international clients. Logistics networks are also highly efficient. They facilitate smooth shipping and customs procedures. This reliability makes Chinese suppliers a dependable choice for international projects. They provide consistent access to innovative and cost-effective door automation technology.

Top Chinese Automatic Door Motor Brands for Sliding Doors

The Chinese market offers several prominent manufacturers specializing in automatic door motors for sliding doors. These companies distinguish themselves through product innovation, quality manufacturing, and extensive project experience.

KBB Automatic Doors

KBB Automatic Doors stands as a leading manufacturer in the automatic door industry. The company provides a comprehensive range of products. These include:

- Platform Screen Doors

- Revolving Doors

- Automatic Sliding Doors

- Interior Automatic Doors

- Hermetic Doors

- Turnstiles and Access Gates

- Swing Doors

- Telescopic Sliding Doors

- Automatic Curved Sliding Doors

- ATM Security Shields

- Spare Parts

- Temperature Detecting Doors

KBB’s GI3000 Interior Automatic Door showcases their commitment to user-centric design and advanced features. This product offers enhanced convenience for various users. It assists housewives with full hands, disabled and elderly individuals, and pet owners. The GI3000 also improves the living environment. It isolates smoke between the kitchen and living room. It saves air conditioning costs by preventing doors from remaining open. The system promotes hygiene by eliminating the need to push doors.

The GI3000 provides a variety of open options. These include wireless switches (infrared and capacitance), infrared radar, keyboard remote switches (wired/wireless), wireless handheld remote control, wireless weight sensing mats, and pet sensors for partial opening. The door features a unique structure and fashionable design, protected by patents. It boasts an exquisite texture and intellectual property-protected design. It is compatible with various door frame materials. These materials include solid wood, composite wood, aluminum, stainless steel, and glass. KBB prioritizes user-friendly functions and thoughtful safe design. The system includes a unique safety mechanism with alternative moving leaves. Force-sensitive door leaves stop and reverse upon obstruction. Anti-squeeze and anti-collision features incorporate rubber protection. The door operates on a safe 36V low voltage.

KBB Automatic Doors has a strong track record with notable installations. Their motors have been used in prestigious projects. These include the “Nest Stadium” and “Water Cube” during the 2008 Beijing Olympic Games. They also supplied motors for “Titanium La Portada,” the highest building in Chile. Other significant projects include “Kuala Lumpur Mid Valley City,” the largest mall in Malaysia, and “Lamcy Plaza,” the largest shopping center in UAE. KBB also supplied motors to “OEM Bank,” a renowned bank in Spain. The company has contributed to 50% of Airport Projects in China for over 10 years.

Olide Automatic Door

Olide Automatic Door offers a diverse portfolio of automatic door solutions. Their products focus on seamless accessibility, durability, and reliability. Olide’s offerings include:

- Automatic sliding doors

- Residential sliding door openers

- Magnetic drive sliding door openers

- Automatic swing doors

- Automatic window openers

- Sliding gate openers

- Swing gate openers

- Automatic sunshade motors

- Automatic hospital doors

- Automatic folding door systems

- Roller Shutters

- Automatic Barrier Gates

- Automatic revolving doors

- Access Control Systems

Olide’s automatic door motors incorporate advanced technology. They feature a DC 24V Brushless Motor with a worm gear reduction for low noise operation. The advanced PWM Pulse Width Control Mode provides reliable and strong driving force. It ensures stable product operation. A full enclosed structure contributes to a long service life. An intelligent 32-bit microprocessor enhances safety. It enables the door to slide in reverse upon obstacle detection. The microprocessor allows intelligent adjustment of opening and closing parameters via the control panel without extra programming. It supports various connectors for different optional access control accessories. One more reducer wheel contributes to more stable operation and lower noise. Durable and light polyurethane rollers are used.

Olide provides a complete and perfect access control system. It supports passcode entry or card swiping with optional keypads. The system offers functions like automatic, exit-only, partial open, and locked modes via an optional five-key selector. It is compatible with various optional accessories. These include foot sensors, touch sensors, and push buttons. Integrated safety beam and microwave sensor functions are available. The optional active radar and infrared safety sensor combines the functions of a safety beam and microwave sensor. This simplifies installation with a single wire connection. A special LM-shaped Girder provides a heavier and stronger beam and cover, similar to ‘Record’ quality.

The core components of Olide’s automatic door systems include:

- Electric Motor (Motor Unit): This is the core component, composed of two main parts.

- Control System: The master controller acts as the command center. It directs the motor or electric lock system using an integrated block with an instruction program. It allows adjustment of opening speed and width.

- Dynamical System:

- Motor: Provides the primary force for opening and closing. It controls acceleration and deceleration.

- Tracks: These guide the door leaf’s movement.

- Spreader and Wheel System: This system hangs door leaves and drives them under dynamic traction.

- Synchronous Belt: This transmits power from the motor to drive the spreader and wheel system.

- Guiding System: This system is located under the door leaf for orientation, positioning, and preventing swinging.

Olide Automatic Door adheres to strict quality standards and holds several important certifications. These include EN 16005:2012 (European Committee for Standardization), ANSI/BHMA A156.10 (United States), and compliance with the Americans with Disabilities Act (ADA). The company also holds ISO9001:2008 international quality standard certification and CE certification.

Ningbo Beifan Automatic Door Factory

Ningbo Beifan Automatic Door Factory, established in 2007, operates with a mission to be a “science, technology and cultural leader” in the door industry. The company specializes in automatic door motors and automatic door operators. It demonstrates a strong commitment to innovation. It offers various products, including efficient swing door operators. The company also provides extensive customization, including OEM and ODM services. It offers flexibility in materials and design to meet specific project needs.

Ningbo Beifan is a leading manufacturer and supplier of automatic doors. They offer a wide range of high-quality products for various applications. Their main products include:

- Automatic sliding doors

- Automatic swing doors

- Automatic revolving doors

- Automatic garage doors

The factory is located in Luotuo Zhenhai, adjacent to the East China Sea. This location provides convenient transportation and a beautiful environment. The factory covers approximately 3,500 square meters. It has a building area of 7,500 square meters. Ningbo Beifan serves a broad international market. Their primary markets include:

- North America

- South America

- Western Europe

- Eastern Europe

- Eastern Asia

- Southeast Asia

- Middle East

- Africa

- Oceania

- Worldwide

Specifically, they have a strong presence in Europe, North & South America, South-east Asia, and Australia.

Raxdoor Automatic Door Motors

Raxdoor establishes itself as a reliable provider of automatic door solutions, particularly for specialized environments. The company has a strong reputation for delivering innovative and dependable cleanroom solutions. Many consider RAX a solid choice for reliable garage doors, offering flexible options and good pricing. Their strength lies in production rather than high-end branding.

RAX Door is a preferred choice for cleanroom applications due to its commitment to quality and industry standard compliance. They emphasize compliance with USDA/FDA and cGMP guidelines, ensuring reliability in regulated industries. Raxdoor specializes in durable and adaptable cleanroom doors. They use corrosion-resistant and chemical-resistant materials. Their doors feature tight seals and easy-to-clean surfaces, ideal for maintaining cleanliness in controlled environments. This focus ensures their products meet the stringent demands of pharmaceutical, biotechnology, and other sensitive industries.

Veze-Autodoor Automatic Door Motors

Veze-Autodoor offers a comprehensive range of automatic door motors and systems, catering to various sliding door applications. Their product portfolio includes diverse solutions for different needs.

- Bi-parting sliding door operators

- Sliding gate opener VEZE-155 (VZ-155)

- Automatic sliding door mechanism (VZ-195)

- Auto sliding door operator (VZ-125)

- VEZE automatic sliding door operators

- Automatic sliding door system (VZ-125)

- Automatic sliding door operator (VZ-125B)

These products demonstrate their commitment to offering versatile and efficient entry solutions.

Veze-Autodoor motors also boast impressive performance metrics, focusing on speed and quiet operation. Their various models offer different specifications to suit specific requirements.

| Metric | Value (mm/s) |

|---|---|

| Opening speed | 100-450 |

| Closing speed | 100-450 |

| Creep speed | 30-100 |

Another model provides enhanced speed capabilities:

| Metric | Value (mm/s) |

|---|---|

| Opening speed | 200-650 |

| Closing speed | 150-550 |

| Noise Level | Greatly noiseless, works quietly |

A third option balances speed and low noise:

| Metric | Value (mm/s) |

|---|---|

| Opening speed | 100-500 |

| Closing speed | 100-500 |

| Creep speed | 30-100 |

| Noise Level | Low |

These specifications highlight Veze-Autodoor’s ability to deliver efficient and quiet automatic door motors, suitable for environments where both performance and minimal disturbance are crucial.

Key Features of Leading Automatic Door Motors

Motor Type and Control Systems

Leading automatic door systems often utilize integrated servo motors. This motor type combines several components into one compact unit. It includes the motor, a feedback device like an encoder or resolver, drive electronics, and a communication interface. This all-in-one design eliminates the need for separate servo drives and complex wiring. It provides exceptional precision and performance for seamless automated operation. The control system is embedded within the motor itself. The servo motor converts electrical energy into mechanical torque for high-performance motion control. An encoder or resolver monitors the motor’s position and speed in real-time. This allows for closed-loop control and accuracy adjustments. Servo drive electronics interpret control signals and adjust motor power, reducing latency. Communication interfaces often feature fieldbus or industrial Ethernet protocols, such as CANopen or EtherCAT. These protocols allow seamless integration into industrial networks. Internal electronics are optimized for heat dissipation, space efficiency, and durability.

Product Range for Sliding Doors

Top manufacturers offer diverse product ranges for various sliding door applications. For instance, some brands provide high-end sliding doors with slim profiles and exceptional insulation. Others focus on uPVC systems, known for excellent thermal insulation and modern aesthetics. Companies like Andersen offer six different types of sliding doors, featuring wood interiors with protective outer shells or Fibrex composite material. They also provide gliding patio doors and contemporary glass sliders with large glass panels and slim frames. Musab offers glass sliding doors, both framed and frameless, ideal for villas, hotels, and retail spaces. They also produce automatic sliding doors with sensors for hands-free entry in malls and hospitals. Internorm specializes in timber-aluminum and uPVC-aluminum sliding doors, offering natural beauty, durability, and excellent insulation. They also provide lift-and-slide doors for wide openings and passive house certified systems for sustainable projects. Vallisco offers sliding doors with various frame materials and slim-line options for luxury homes and commercial spaces.

Reputation and Certifications

Reputation and certifications are crucial indicators of quality and reliability for automatic door systems. Manufacturers often obtain various certifications to demonstrate compliance with international standards. Common certifications include CE, RCM, EN12453, and EN12445 approvals. These certifications ensure products meet specific safety, health, and environmental protection requirements. UL Solutions also provides door hardware testing and certification services. This indicates UL certification as a recognized standard in the global market. These certifications assure customers that the products meet rigorous quality and safety benchmarks.

Factors for Selecting Automatic Door Motor Suppliers

Motor Power and Door Capacity

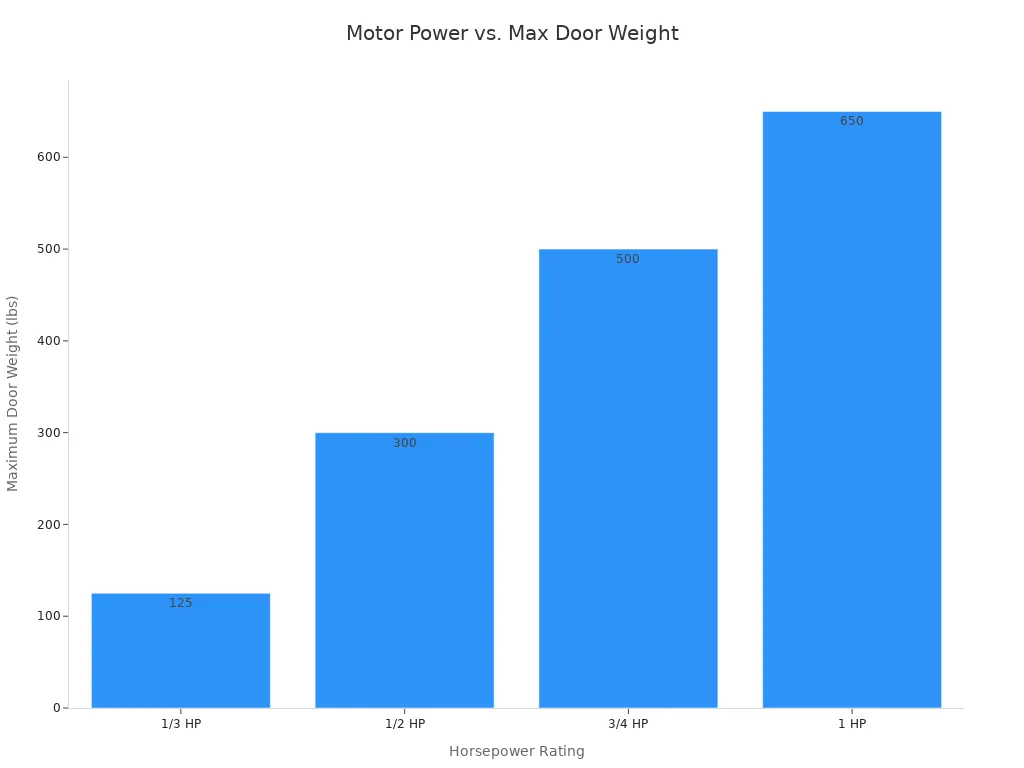

Selecting the correct motor power is crucial for efficient and reliable automatic door operation. The motor’s horsepower directly correlates with the maximum weight and size of the door it can effectively move. Suppliers provide specifications detailing these capacities. For instance, a 1/3 HP motor handles doors up to 125 lbs, while a 1 HP motor manages doors up to 650 lbs. This relationship ensures the motor does not strain, which prevents premature wear.

| Horsepower Rating | Maximum Door Weight |

|---|---|

| 1/3 HP | 0-125 lbs |

| 1/2 HP | 0-300 lbs |

| 3/4 HP | 0-500 lbs |

| 1 HP | 0-650 lbs |

The chart visually represents this direct correlation. As horsepower increases, the maximum door weight capacity also increases. It is important to note that DC motors often receive a ‘Horse Power Similar’ (HPS) designation. This compares their pulling force to an AC motor. These ratings assume a balanced, well-maintained door with average usage.

Safety Features and Compliance

Safety features are paramount when choosing an automatic door motor supplier. Leading suppliers integrate advanced safety mechanisms into their products. These include obstacle detection sensors, which stop and reverse the door upon sensing an obstruction. Emergency release functions allow manual operation during power outages. Compliance with international safety standards, such as EN 16005 or ANSI/BHMA A156.10, ensures the doors meet rigorous safety benchmarks. Suppliers must provide documentation confirming these certifications. This guarantees the system operates safely for all users.

Durability and Lifespan of Automatic Door Motors

The durability and expected lifespan of automatic door motors significantly impact long-term operational costs. High-quality materials and robust construction contribute to a longer service life. Suppliers should use components designed for continuous operation and resistance to wear and tear. Factors like motor type, gear materials, and overall build quality influence longevity. A longer lifespan reduces the frequency of replacements and maintenance. This provides better value over time. Reputable suppliers offer products with proven durability. They often provide extended warranties, reflecting their confidence in the product’s lifespan.

After-Sales Support and Warranty

Reputable suppliers offer robust after-sales support and comprehensive warranties. These services ensure the long-term performance and reliability of automatic door motors. A typical warranty covers factory labor and parts for in-house repairs. It also includes parts and labor for on-site repairs, though it usually excludes travel and living expenses. The warranty process often involves customer contact with technical support for initial determination. This leads to various Return Material Authorization (RMA) types, such as Warranty Parts Replacement or Warranty Product Replacement. For replacement RMAs, a purchase order is necessary. The supplier invoices the replacement unit upon shipment. They issue credit after receiving and evaluating the defective material within 30 days.

Beyond warranties, suppliers provide extensive support services. Many offer 24/7/365 automatic door service and support. They ensure responsive and trustworthy same-day and emergency repairs at competitive rates. Preventative maintenance programs include regularly scheduled visits by fully certified door service technicians. These technicians perform scheduled 14-point inspections and AAADM-certified inspections. They identify deficiencies, ensure compliance with ANSI standards and building codes, and perform necessary tests, adjustments, and lubrication. Suppliers also offer repair services for almost any make, model, or type of automatic, manual, and revolving doors. They provide robust reporting capabilities for each door, including service history, location, manufacturer, warranty status, and contract status. Products are often backwards compatible and designed for simple serviceability, allowing for fast fixes.

Customization Capabilities

Leading automatic door motor suppliers offer extensive customization capabilities. These options allow clients to tailor solutions to specific aesthetic and functional requirements. Customers can choose from a wide range of glazing products. These include clear, frosted, colored, or decorative glass up to 1 inch thick. Other options feature markerboard glazing, switchable privacy glass, integral blinds or louvers, and glass with specialty applied films or graphics.

Door materials also offer diverse choices. These include flush wood, flush laminate, wood stile and rail with glass vision lite, resins, or other solid surface materials. Finish options are plentiful, encompassing standard and custom finishes, various veneers and species for wood, plastic laminates, and standard silver or custom color finishes for aluminum stile and rail. Suppliers also provide specialty doors, such as lead-lined or hollow metal steel doors. Control options enhance functionality. These include 4-function remote controls, function keypads, touchless door actuators, interior and exterior sensors, ladder pulls, and flush pulls.

Customization extends to overall frame width, with options like 84-108 inches for single slide doors and 120-168 inches for bi-part doors. Glazing options include 1/4 inch monolithic, 1/2 inch monolithic, 5/8 inch insulated, and 1 inch insulated glass. Access control options feature solenoid locks and panic hardware with solenoid locks. Suppliers also offer heavy-duty construction and specific ratings or certifications, such as Clean Room Certified.

Verifying Supplier Reliability for Automatic Door Motors

Industry Certifications and Standards

Verifying a supplier’s reliability begins with examining their industry certifications and adherence to international standards. These credentials confirm a manufacturer’s commitment to quality, safety, and environmental responsibility. Key certifications include CE, which indicates conformity with European health, safety, and environmental protection standards. The EN 16005 standard specifically addresses power-operated pedestrian doors, ensuring safety during use. In the United States, ANSI/BHMA A156.10 sets standards for power-operated pedestrian doors, guaranteeing both safety and performance.

Manufacturers also pursue broader quality and environmental management certifications.

| Certification/Standard | Description |

|---|---|

| IATF 16949:2016 | A quality management system standard specifically for the automotive industry, applicable to motors and electronics. |

| RoHS Compliance | Restricts the use of hazardous substances in electrical and electronic equipment, ensuring environmental safety. |

| ISO 14001 | Provides a framework for establishing an effective environmental management system within an organization. |

| UL | Offers safety-related certification, testing, and validation services for various products and components. |

| CSA | Provides safety certification and testing for products intended for sale in the US and Canada. |

| CE | Signifies that a product meets European Conformity standards. |

| ISO 9001 | A globally recognized standard for quality management systems, emphasizing a quality-centric business approach. |

These certifications collectively assure buyers of a product’s quality and compliance.

Customer Testimonials and Case Studies

Customer testimonials and case studies offer valuable insights into a supplier’s real-world performance and customer satisfaction. These resources provide concrete examples of how a supplier’s automatic door motors perform in various applications. Nidec Drives (Control Techniques) provides a case study titled ‘Automatic Door Opener‘. This study details their provision of a simplified, low-cost variable frequency drive solution for an automatic door opener. They integrated control logic into the drive software to improve reliability, save space, and reduce installation costs for their customer.

Industrial Door Company features a dedicated ‘Case Studies’ page, showcasing detailed examples of their work. Caesar Door also mentions ‘Testimonials from the Field‘ on their page, indicating available customer feedback. Testimonials often highlight a company’s service quality. Rana Cheema praised a company for “High quality work, great communication, local ownership, fair price.” Amanda Shaffer gave “5 stars for customer care,” noting a service tech repaired closures and waived labor charges. Alec S. found working with a company’s team a “pleasure,” describing them as “respectful” and efficient.

Manufacturing Capabilities and Quality Control

Robust manufacturing capabilities and stringent quality control processes are essential for producing reliable automatic door motors. Leading manufacturers implement comprehensive quality management systems. Horton adheres to ISO 9001 standards, tracking production and checks. Their products undergo testing for durability, safety, and ease of use. Automatic Systems manufactures most products in-house using quality European materials. They test each item before shipping for wear, speed, motor control, and locking safety. Hörmann produces most parts internally, allowing material and process tracking. Their products undergo strict factory testing.

NINGBO BEIFAN holds ISO9001:2008, ISO14001:2004, and CE international certifications. They adhere to ISO9000 certification standards, utilizing leading production equipment to control each process. They rigorously inspect raw materials to meet national standards. Each equipment undergoes testing with various data, high temperature and high pressure aging, and one hour of actual drag load operation. They source core components from leading international suppliers like IR-power semiconductor and ST-STMicroelectronics. Many companies conduct extensive testing. They use monotonic and cyclic testing to identify mechanical properties. Production-line bench testing continuously checks products throughout the production line and after assembly. High-cycle fatigue testing determines the number of cycles to fracture.

Export Experience and Logistics

A supplier’s extensive export experience and robust logistics capabilities are critical for international buyers. Experienced suppliers understand global trade regulations and customs procedures. This knowledge ensures smooth transactions and avoids delays. They manage documentation efficiently, preventing complications during shipping. Their expertise simplifies the procurement process for clients worldwide.

Efficient logistics networks guarantee timely and secure delivery of automatic door motors. Suppliers often partner with reliable shipping companies. These partnerships ensure products reach their destination safely. They also track shipments, providing real-time updates to customers. This transparency builds trust and confidence. A well-managed supply chain minimizes transit times and reduces potential damage.

Delivery times for automatic door motors typically range from 10 to 45 days. This timeframe begins after the supplier receives the deposit. The exact duration depends on the order quantity and specific requirements. Larger orders or highly customized products may require more production time. Suppliers communicate these timelines clearly to manage customer expectations.

Suppliers with strong export experience also offer various shipping options. They can arrange sea freight for large volumes or air freight for urgent deliveries. They advise on the most cost-effective and efficient method for each order. Their ability to handle diverse logistical challenges demonstrates their reliability. This comprehensive approach ensures customers receive their automatic door motors promptly and without hassle. Choosing a supplier with proven export and logistics capabilities streamlines international purchasing.

Selecting a reliable Chinese automatic door motor is crucial for long-term performance. Focus on reputable brands and key selection criteria for optimal results. Prioritize motors with robust technical specifications, including appropriate torque and voltage compatibility. Look for ISO 9001 certification and rigorous third-party testing for quality assurance. Ensure suppliers offer clear warranties and reliable technical support. These considerations guarantee an effortless and secure entry solution for your sliding doors.

- Technical Specifications: Verify torque range, voltage, environmental protection (e.g., IP54), and noise levels.

- Quality Assurance: Prioritize ISO 9001 certification and rigorous testing.

- After-Sales Support: Confirm warranty terms and technical assistance availability.

FAQ

What quality standards do Chinese automatic door motors meet?

Many Chinese manufacturers adhere to international quality standards. They often hold certifications like ISO 9001, CE, and EN 16005. These certifications ensure products meet rigorous safety and performance benchmarks.

Do Chinese automatic door motor suppliers offer warranties?

Yes, reputable Chinese suppliers typically provide warranties. These warranties cover factory labor and parts for in-house repairs. They also include parts and labor for on-site repairs. Customers should confirm specific warranty terms with their chosen supplier.

Can I customize automatic door motors for specific projects?

Leading Chinese suppliers offer extensive customization capabilities. They provide options for glazing, door materials, and finishes. Clients can also choose various control options and specialized door types. This allows tailoring solutions to unique project requirements.

How do I ensure the safety of automatic door motors?

Suppliers integrate advanced safety features into their products. These include obstacle detection sensors and emergency release functions. Compliance with international safety standards like EN 16005 or ANSI/BHMA A156.10 is also crucial. Always verify these safety certifications.