Many businesses aim to improve their entryways. An Automatic Door System offers easy access for all visitors. This includes individuals using wheelchairs, which ensures ADA compliance. Such systems also create a professional appearance for any establishment. They improve hygiene by reducing touch points. Selecting the right Automatic Sliding Door Operator is crucial for these benefits. Businesses must consider various factors. This ensures optimal performance, safety, and cost-effectiveness. An informed decision helps meet specific operational needs. For example, a reliable Electric Sliding Door Operator, perhaps featuring a Beifan Automatic Door Motor, makes a significant difference. This choice is critical for the best automatic sliding door operator for commercial use. Businesses also evaluate Automatic Swing Door Opener Selection for different entry requirements.

Key Takeaways

- Understand your business needs, like how many people use the door and what kind of business you have, before choosing an automatic door.

- Learn about different types of automatic door operators, such as standard, heavy-duty, and low-energy, to find the best fit.

- Look for advanced features like smart control systems, good sensors, and self-checking tools to make sure the door works well and is safe.

- Always put safety first by choosing doors that meet industry rules and have features like emergency exits and ways to detect things in the door’s path.

- Think about the full cost of the door, including how much it costs to install, maintain, and how long it will last, not just the buying price.

Assess Business Needs for Your Automatic Sliding Door Operator

Choosing the right automatic door operator begins with a clear understanding of a business’s specific needs. This initial assessment ensures the chosen system aligns perfectly with operational demands and environmental factors.

Determine Daily Traffic Volume and Usage Patterns

The volume of daily traffic significantly impacts the type of automatic door operator a business needs. Doors in busy areas, like retail stores or hospitals, experience frequent opening and closing cycles daily. This constant use demands a more robust and durable operator. An operator designed for light use will quickly fail under continuous heavy-duty operation. Therefore, businesses must assess the expected number of daily cycles to determine the required strength and longevity of the chosen system. High-traffic environments demand operators built for continuous operation and higher duty cycles.

| Traffic Area | Inspection Frequency |

|---|---|

| High-traffic | Every 3-6 months |

| Low-traffic | Annually |

Consider Business Type and Specific Requirements

Different business types have unique requirements for their automatic doors. Healthcare facilities, for instance, face strict regulations. The NFPA 101 – Life Safety Code (2021 Edition) requires a ‘swing-out feature’ for many doors, meaning the door assembly must swing from any position to provide full use of the required opening width when force applies from the egress side. The International Building Code (IBC) (2021 Edition) Section 1010.3.2 – Power-Operated Doors, mandates similar capabilities. For access control, doors must unlatch with one motion for egress, without requiring a key or special knowledge. The hardware must also be operable without tight grasping or twisting. Standard automatic sliding doors are ideal for many healthcare applications, including ER entrances, often featuring a utility breakaway function. Other specialized doors, like the Dura-Shield™ Blast Resistant Door or Dura-Storm™ Automatic Sliding Hurricane Doors, cater to specific safety and environmental challenges.

Evaluate Door Opening Speed Needs

The required door opening speed varies based on the business environment. A fast opening speed is crucial for high-traffic areas to maintain smooth pedestrian flow and prevent bottlenecks. For example, a supermarket entrance benefits from a quick-opening door to accommodate a continuous stream of customers. Conversely, a slower opening speed might be acceptable, or even preferred, in environments where security or climate control is a higher priority, such as a controlled access point in an office building. Businesses must balance speed with other factors like energy efficiency and safety.

Understand Key Types of Automatic Sliding Door Operators

Businesses find many different automatic door operators available. Each type serves specific needs and environments. Understanding these differences helps a business choose the best system.

Standard Automatic Operators

Standard automatic operators are a popular choice for many commercial settings. They offer reliable performance for everyday use. People often see these operators on the outside doors of large retail businesses. They also commonly appear in elevators (lifts). These versatile systems work well in various building types, including:

- Retail buildings

- Industrial buildings

- Commercial buildings

- Education buildings

- Healthcare buildings

These operators provide convenience and accessibility for a wide range of traffic volumes.

Telescopic and Heavy-Duty Operators

Some situations demand more robust solutions. Telescopic operators allow for wider clear openings in limited spaces. They use multiple door panels that stack neatly. Heavy-duty operators, on the other hand, handle exceptionally large and heavy doors. These powerful systems can manage significant weight. For example, a heavy-duty automatic sliding door operator can handle a single door weighing up to 250 kg. For bi-parting doors, it manages two doors, each weighing up to 200 kg. A 36V motor typically powers these heavy-duty systems.

| Door Type | Maximum Door Weight (kg) |

|---|---|

| Single | 1×250 |

| Bi-parting | 2×200 |

Low-Energy vs. High-Energy Operators

Businesses also choose between low-energy and high-energy automatic door operators. High-energy operators move doors quickly and with more force. They require safety sensors to detect people and objects, ensuring safe operation. Low-energy operators move doors at a slower speed and with less force. They do not always require the same extensive safety sensors as high-energy models. This makes them suitable for areas where people move more slowly or where safety is a primary concern without high traffic speeds.

Residential Operators

Residential operators cater to individual homes and smaller private spaces. They differ significantly from commercial systems. Homeowners often prioritize convenience, aesthetics, and quiet operation. These operators typically handle lighter doors and less frequent use compared to their commercial counterparts. They offer a touch of modern luxury and improved accessibility for residents.

Many residential operators focus on seamless integration with smart home systems. This allows homeowners to control their doors using a smartphone app or voice commands. Imagine opening your patio door with a simple voice prompt! This level of convenience enhances daily living.

Key features homeowners look for include:

- Quiet Operation: Nobody wants a noisy door disrupting their home environment.

- Sleek Design: Operators should blend in with home decor, not stand out.

- Smart Home Compatibility: Integration with existing smart devices adds value.

- Enhanced Security: Secure locking mechanisms provide peace of mind.

Installation for residential operators is often simpler. This makes them appealing for local contractors or even skilled DIY enthusiasts. However, professional installation always ensures optimal performance and safety. These systems provide easy access for family members and guests. They also offer a convenient way to move large items in and out of the house. Residential operators bring modern functionality and comfort directly to your home. They represent a smart investment for homeowners seeking convenience and accessibility.

| Feature | Residential Operator | Commercial Operator |

|---|---|---|

| Usage | Low-to-moderate traffic | High-to-very high traffic |

| Focus | Convenience, aesthetics, quietness | Durability, speed, safety compliance |

| Integration | Smart home systems | Building management systems |

| Door Weight | Lighter doors | Heavier, larger doors |

Explore Technologies and Features of Automatic Sliding Door Operators

Modern automatic sliding doors are more than just moving panels. They use advanced technology to ensure smooth, safe, and efficient operation. Understanding these features helps businesses choose the best system for their needs.

Electro-Mechanical and Microprocessor Control Systems

The “brain” of an automatic door system is its control unit. Microprocessor control units act as the electronic brain. They receive input from sensors and activation devices. Then, they process this information and send commands to the motor and other parts. These units interpret sensor signals to decide when to open or close. They also monitor trigger sensors for approaching people and safety sensors for obstructions. Motor control involves driving the electric motor with programmable speed and torque. This ensures smooth operation, limits force, and uses feedback for precise motion and obstruction detection. The systems also coordinate and time functions. They maintain hold-open times and coordinate multiple doors, like in airlock functions. They offer various modes, such as automatic, hold-open, and night lock. These systems can also connect with other building systems, such as fire alarms or security systems, for emergency overrides. They include self-diagnostic functions to check component health and show error codes.

Sensor Technologies for Motion and Presence Detection

Sensors are crucial for safety and activation. They detect when someone approaches the door or stands in its path. Many systems use a combination of technologies. For example, the BEA IXIO–DT1 combines microwave radar for door activation with infrared technology for pedestrian safety. Similarly, the SSR-3F is a combination microwave and active infrared sensor. It provides both activation and safety for automatic sliding doors. The OPTEX X-Zone T Sensor also uses both infrared and microwave sensing for precise activation. Common sensor types include:

- Infrared

- Microwave

- Dual-technology (a combination of infrared and microwave)

Advanced Features and Diagnostics

Today’s automatic sliding door operators offer more than basic functions. Many systems have self-diagnostic features. These features tell maintenance staff about potential problems. This allows for quick repairs and less downtime. Advanced doors can connect to building management systems. This allows remote monitoring and diagnostics for maintenance. Modern automatic sliding door operators use IoT platforms and cloud-based software. This provides remote monitoring and diagnostic abilities. Maintenance managers can oversee door systems from afar. They receive real-time updates and alerts about potential issues. This remote access helps with fast diagnostics and troubleshooting. It minimizes downtime and lowers maintenance costs. Data from door operations can also help predict maintenance needs. This keeps the doors in top working condition.

Prioritize Safety and Compliance for Your Automatic Sliding Door Operator

Safety is paramount when choosing an automatic door system. Businesses must ensure their doors protect everyone and meet all legal requirements. This focus prevents accidents and avoids costly penalties.

ANSI/BHMA A156.10 Standards and Certifications

Industry standards like ANSI/BHMA A156.10 set the bar for automatic door safety. These standards are crucial for building safety and performance. They cover important areas like egress and fire protection. Building codes, such as the International Building Code and NFPA 101, often reference them. These standards also ensure accessibility, making doors usable for everyone. Power-operated doors are common on accessible routes. They even help with sustainability through durability and energy conservation.

The standards specify many safety details. For example, they require features to reduce injury or entrapment. Signage is also very important. The “Automatic Door” sign must have exact font size, color, and placement. If a motion sensor starts a low-energy operator, it needs monitored presence sensors or safety control mats. These sensors must work and talk to the door control system. If a sensor fault happens, the door must stop working until someone fixes it. For fire door assemblies, operators must meet UL 10C or NFPA 252 standards.

For peace of mind, look for AAADM (American Association of Automatic Door Manufacturers) certification. This certification means technicians understand ANSI standards A156.10, A156.19, and A156.38. An AAADM-certified technician ensures safe and efficient operation for your Automatic Sliding Door Operator.

Emergency Egress and Breakout Capabilities

Automatic sliding doors must allow people to exit quickly in an emergency. This means they need a “breakout” or “breakaway” feature. This feature lets people push the door panels open manually, even if the power fails. Locking hardware must also be easy to use. It needs to unlatch all locks with just one motion.

Different types of locking hardware have specific rules. For example, panic hardware is often required in places like schools or assembly areas with many people. Access control systems must also allow free egress. This means people can always exit without a key or special knowledge. Doors must also have clear signs. Signs like “AUTOMATIC DOOR” and “IN EMERGENCY PUSH TO OPEN” guide users during normal operation and emergencies.

Obstacle Detection and Reversal Mechanisms

Modern automatic doors use smart technology to prevent collisions. Obstacle detection systems are key to this safety. They stop or reverse the door if something is in its path.

Several sensor types work together to achieve this:

- Infrared (IR) Sensors: These send out infrared beams. If an obstacle breaks the beam, the door stops.

- Microwave Sensors: They send out continuous microwave signals. When signals reflect off an object, the door stops or reverses.

- Ultrasonic Sensors: These use sound waves to find obstacles. They measure how long it takes for a sound pulse to return.

- Contact Sensors: These are pressure-sensitive mats or strips. If they feel resistance, the door stops or reverses.

- Safety Edges: These flexible strips on door panels compress if they hit an obstacle. This signals the door to stop or reverse.

Advanced control systems combine data from these sensors. They use smart algorithms to make real-time decisions. This greatly improves safety and reduces the chance of accidents.

Battery Backup for Power Outages

Power outages can happen unexpectedly. When they do, businesses still need their automatic doors to work. A reliable battery backup system ensures doors remain operational. This is crucial for safety, security, and continued access.

Many building codes recognize the importance of backup power. For example, the California Building Code (Section 1133B.2.5) has specific rules. It mandates that automatic sliding door operators in buildings with 150 or more occupants must have a backup power source. This source must cycle the door at least 100 times during an outage. This ensures people can still enter and exit safely.

The actual time a backup power source lasts depends on a few things:

- The battery’s capacity. A larger battery stores more power.

- The door controller’s power demands. Some systems use more energy than others.

- How often people use the door. More frequent use drains the battery faster.

Businesses want to know their backup system will perform when needed. One automatic door supplier shared their test results:

During testing, their J60i-350 backup power unit successfully operated automatic doors over 90 times on backup power alone, demonstrating reliable real-world protection.

This kind of performance gives businesses confidence. It means their doors will keep working even when the main power goes out. Investing in a good battery backup system protects your business and its visitors during emergencies. It provides peace of mind and maintains essential functions. 🔋

Evaluate Installation, Maintenance, and Total Cost of Ownership for Your Automatic Sliding Door Operator

Choosing an automatic door system involves more than just the initial purchase. Businesses must also think about installation, ongoing maintenance, and the total cost over time. These factors greatly affect the system’s long-term value and performance.

Installation Complexity and Professional Requirements

Installing an automatic sliding door operator is a complex job. It requires specialized skills to ensure safety and proper function. Professional installation is always the best choice. Technicians often need specific certifications. For example, to become an AAADM Certified Inspector for automatic sliding door operators, individuals must have experience in the automatic pedestrian door industry. They need at least six months of work experience right before applying for the training course. Or, they can have 90 days of experience if they also finished a factory training course from an AAADM member. This ensures the installer understands all safety standards and best practices.

Long-Term Maintenance Needs and Service Contracts

Automatic doors need regular care to work well and last a long time. Maintenance schedules depend on how much people use the door.

| Maintenance Frequency | Traffic Level / Operational Needs | Example Facilities |

|---|---|---|

| Quarterly | Heavy daily traffic, critical operational needs | Hospitals, medical centers, retail stores, airports, hotels, large commercial campuses |

| Semi-Annual | Mid-traffic, regular use | Office buildings, banks, financial institutions, senior care facilities, educational campuses |

| Annual | Low to moderate traffic, limited-use areas | Warehouses, administrative offices, small clinics, storage buildings |

Regular maintenance includes cleaning guide tracks, checking safety sensors, and calibrating motion detectors. Technicians also tighten hardware and verify smooth operation. They inspect all components and make necessary repairs. Some parts need more attention than others. Sensors need regular cleaning to prevent issues from dust. Moving parts like hinges, rollers, and tracks need lubrication. The door itself needs cleaning to keep sensors clear.

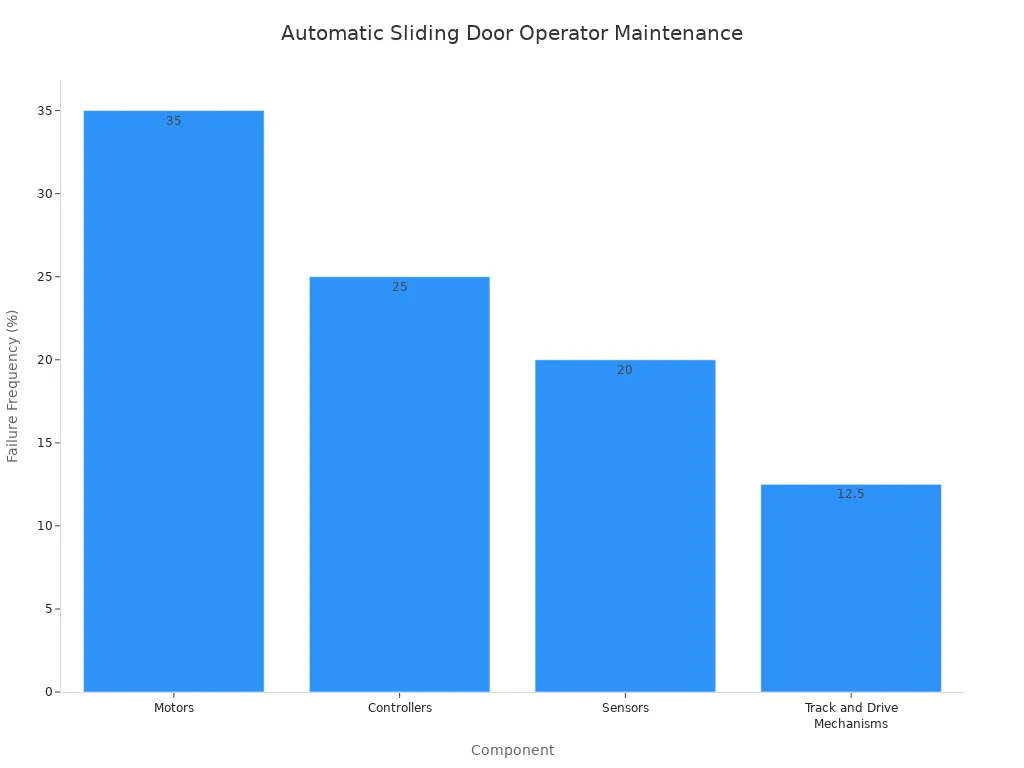

Motors, controllers, and sensors often have higher failure rates. Regular checks help catch problems early.

Initial Purchase Cost vs. Total Cost of Ownership

The total cost of ownership (TCO) for automatic sliding doors includes more than just the price tag. It covers the purchase price, installation costs, energy use, maintenance expenses, and how often you replace parts. Routine maintenance, often every six months, helps prevent bigger problems. This involves cleaning tracks, lubricating gears, and testing sensors. Innovations like dual-motor redundancy and self-diagnostic systems improve reliability. They also reduce downtime. These advancements lower long-term operational costs, including maintenance. Regular maintenance prevents small wear from becoming big defects. Experts can find and fix early signs of problems. This keeps the door safe and working, reducing costly emergency repairs.

Warranty and Manufacturer Support

A strong warranty and reliable manufacturer support are crucial for any automatic door operator. These factors protect a business’s investment and ensure long-term operational peace of mind. Manufacturers often provide a limited warranty for their products. For example, NABCO Entrances, Inc. offers a limited warranty for its automatic sliding door operators for 12 months after the shipment date. This warranty period gives businesses confidence in their purchase.

Manufacturers also offer extensive post-purchase support. This support helps businesses keep their doors running smoothly. Many companies provide a global network of support and strong after-sales systems.

| Manufacturer | Support & Service |

|---|---|

| Assa Abloy AB | Global network, strong after-sales system |

| Hörmann Group | Europe-based reps, responsive service teams |

| Vallisco | Direct factory support, SEA/Europe focused |

| NABCO | Certified installers, global partners |

| Horton Automatics | North American service hubs, dealers |

| Automatic Systems | Regional tech support, secure entry experts |

| VEZE | OEM support, flexible for overseas clients |

| CUMU | Responsive team, English-speaking support |

Horton, for instance, provides expert installation, responsive service, and experienced field consultation. They also have a comprehensive distributor network and serve customers around the globe. Businesses can find various resources to help them with their automatic doors:

- Automatic Sliding Door Resources

- Automatic Sliding Door Sticker Placement and Decal Requirements

- Automatic Door Sensor Help Center

- Frequently Asked Questions

- Repair and Service

- Retrofit Kits

- Automatic Door Opener Learning Resources

- Installation Guides & Videos (Stanley, Horton)

- High-quality replacement automatic door parts and components for all major automatic door brands.

Some manufacturers also offer specific instruction PDFs and videos for registered members. These include Dorma, Doromatic, Horton, Keane Monroe / K-M Systems, Nabco / Gyro Tech, Record, and Stanley. Businesses can often find a local or international distributor or contact a representative directly for assistance. This comprehensive support ensures businesses get the help they need, whenever they need it.

Selecting the ideal Automatic Sliding Door Operator empowers businesses to enhance their operations. This careful decision boosts efficiency, strengthens security, and significantly improves the customer experience. Businesses ensure long-term value and maintain full compliance with important industry standards. Making an informed choice now guarantees a smart and lasting investment for any establishment.

FAQ

What is the main benefit of an automatic sliding door for a business?

Automatic sliding doors offer great convenience and accessibility. They allow easy entry for all visitors, including those with disabilities. This also improves hygiene by reducing touchpoints. Businesses often find they create a professional and welcoming entrance.

How often do automatic sliding doors need maintenance?

Maintenance frequency depends on traffic. High-traffic doors, like those in retail, need checks every 3-6 months. Low-traffic doors, such as in small offices, usually require annual inspections. Regular maintenance ensures safe and efficient operation.

Do automatic sliding doors have safety features?

Yes, they do. Modern automatic doors include obstacle detection and reversal mechanisms. They also have emergency egress capabilities. Many meet strict safety standards like ANSI/BHMA A156.10. Battery backups ensure operation during power outages.

Can an automatic sliding door help my business save energy?

Yes, they can. Automatic doors minimize the time doors stay open. This helps maintain indoor temperatures. It reduces heating and cooling costs. Proper installation and maintenance further enhance energy efficiency.