The ideal actuator for commercial doors balances accessibility, efficiency, and safety. This critical component, an Automatic Door Operator, ensures smooth door movement, preventing mechanical strain. A correctly chosen Automatic Door Motor provides sufficient force for heavy doors, prevents overheating, and ensures durability. Selecting appropriate Automatic Door Motors is vital for an effective Automatic Door System. It guarantees compliance and enhances user convenience. An experienced Automatic Door Motor Manufacturer guides this process for specialized needs like a Sliding Door Motor.

Key Takeaways

- Choose the right automatic door motor based on how many people use the door. Busy areas need strong motors, while quieter places can use slower, safer ones.

- Always put safety first. Make sure the door motor has features like sensors to prevent accidents. It must follow safety rules like ANSI standards.

- Make sure the door works for everyone. It needs to follow ADA rules so people with disabilities can use it easily.

- Think about where the door is. If it is outside or in a tough place, the motor needs to be strong and last a long time against weather or dirt.

- Consider the total cost. This includes the price of the motor, how much it costs to put in, and how much it will cost to fix and run over time.

Understanding Automatic Door Motors: Types and Applications

Selecting the correct automatic door motor involves understanding the different types available and their specific applications. Each actuator type offers distinct features tailored to various operational demands and environmental conditions.

Full-Energy Actuators for High-Traffic Areas

Full-energy actuators operate doors at higher speeds and with greater force, making them ideal for locations with heavy pedestrian traffic. These areas include main entrances of hospitals, airports, and large retail stores. The rapid operation ensures efficient traffic flow and minimizes bottlenecks. Building codes often mandate full-energy actuators in specific scenarios to manage high volumes of people.

| Building Status | Applications | Qualifications |

|---|---|---|

| Newly Constructed Buildings | Air handling system and all zones served by the system | Individual systems supplying more than three zones and with design heating or cooling capacity of 300 kBtu/h and larger |

| Newly Constructed Buildings | Chilled water plant and all coils and terminal units served by the system | Individual plants supplying more than three zones and with design cooling capacity of 300 kBtu/h (87.9 kW) and larger |

| Newly Constructed Buildings | Hot water plant and all coils and terminal units served by the system | Individual plants supplying more than three zones and with design heating capacity of 300 kBtu/h (87.9 kW) and larger |

| Additions or Alterations | Zone terminal unit such as VAV box | Where existing zones served by the same air handling, chilled water, or hot water systems that have DDC |

| Additions or Alterations | Air handling system or fan coil | Where existing air handling system(s) and fan coil(s) served by the same chilled or hot water plant have DDC |

| Additions or Alterations | New air handling system and all new zones served by the system | Individual systems with design heating or cooling capacity of 300 kBtu/h and larger and supplying more than three zones and more than 75 percent of zones are new |

| Additions or Alterations | New or upgraded chilled water plant | Where all chillers are new and plant design cooling capacity is 300 kBtu/h (87.9 kW) and larger |

| Additions or Alterations | New or upgraded hot water plant | Where all boilers are new and plant design heating capacity is 300 kBtu/h (87.9 kW) and larger |

These powerful Automatic Door Motors must comply with stringent safety standards, particularly ANSI 156.10. This standard requires enhanced safety measures, including sensors and guard rails, to prevent accidents. If a low-energy operator incorporates motion sensors, it becomes reclassified as a full-energy opening under ANSI 156.10, necessitating these stricter safety features.

Safety zones are critical for full-energy actuators. The safety zone must extend at least 5 inches (125 mm) beyond the door’s leading edge when open. If a door-mounted sensor creates a safety zone, it must actively cover up to 5 inches (125 mm) from the door face. This sensor must detect a person at least 28 inches (710 mm) tall in the swing path, prompting the door to reverse, stop, or slow down.

Other important safety considerations for full-energy actuators include:

- Activation and Safety Zones: If the distance between two non-overlapping zones exceeds 8 inches (205 mm) when sensors are used for both activation and safety, the system must include a safety control mat, a presence sensor, a 4-second minimum closing delay, or a door-mounted sensor on the non-swing side.

- Knowing Act Door Actuation: An activating device must be visible from the door, installed at a height of 36 to 48 inches (915 to 1220 mm), and located a maximum of 12 feet (3.7 m) from the door’s center. The door must remain open for at least 5 seconds after releasing the device and include safety zones.

- Entrapment Protection: Measurements for entrapment protection must occur under neutral air pressure conditions.

- General Performance: This includes requirements for latch check, manual opening force (no more than 30 lbf or 133 N in power failure), and break-away devices (no more than 50 lbf or 222 N to open). Break-away devices must undergo extensive cycling and salt spray tests.

- Signage: Knowing Act Doors must display signage stating “Automatic Door – Activate Switch to Operate” in 1/2 inch (13 mm) letters.

Low-Energy Actuators for Controlled Environments

Low-energy actuators operate doors at slower speeds and with reduced force. They are suitable for environments where users might have limited mobility or where a more controlled, deliberate door movement is preferred. These settings include offices, restrooms, and assisted living facilities. They prioritize user safety by minimizing the risk of impact.

Low-energy automatic door actuators, adhering to ANSI A156.19, have specific speed requirements:

- Opening Time:

- Doors must adjust so the opening time to backcheck or 80 degrees (whichever comes first) is 3 seconds or longer.

- Backcheck should not occur before 60 degrees of opening.

- The total opening time to fully open has specific limits.

- Closing Time:

- Doors must adjust to close from 90 degrees to 10 degrees in 3 seconds or longer.

- Doors must adjust to close from 10 degrees to fully closed in no less than 1.5 seconds.

These slower speeds and lower forces make them inherently safer for environments with vulnerable populations.

Power-Assist Actuators for Heavy Doors

Power-assist actuators do not fully automate door operation. Instead, they reduce the manual effort required to open heavy doors. They are particularly useful for large, heavy doors in places like warehouses, industrial facilities, or even some institutional buildings where full automation is unnecessary or impractical. These actuators provide a boost, making heavy doors feel lighter and easier to operate. For example, a model like the SD3108 can support a door weight of up to 120 kgs.

| Model | Door weight |

|---|---|

| SD3108 | 120 kgs |

This type of automatic door motor enhances accessibility without the complexity or cost of a full automation system.

Key Selection Criteria for Commercial Automatic Door Motors

Assessing Traffic Volume and Flow

Assessing traffic volume and flow represents a foundational step in selecting the appropriate automatic door motor. The daily pedestrian traffic volume directly dictates the required duty cycle for the operator. Higher daily usage necessitates a more robust motor, even for applications that might seem less demanding. Commercial automatic door motors are specifically engineered for heavy-duty applications and high-traffic areas, indicating that increased pedestrian volume directly influences the motor’s design requirements for reliability, efficiency, and strong driving force. The service life of these motors also links to usage frequency. For instance, high-traffic doors, experiencing over 10,000 daily users, wear out faster than low-traffic doors, which see fewer than 1,000 daily users. While commercial automatic door operators typically last between 10 to 15 years, many businesses replace them at or before the ten-year mark due to constant use and a tendency to prioritize repairs over preventative maintenance. Therefore, understanding the expected traffic helps specify a motor capable of enduring the operational demands.

Prioritizing Safety Features and Requirements

Prioritizing safety features and requirements is paramount for any commercial door installation. Actuators must incorporate mechanisms that protect users from injury, especially in high-traffic environments. These features include presence sensors, emergency stop buttons, and fail-safe operations that ensure doors remain accessible or secure during power outages. Compliance with industry standards, such as ANSI A156.10 for full-energy operators and ANSI A156.19 for low-energy operators, ensures the system meets established safety benchmarks. Regular maintenance and inspections are crucial for verifying the continued functionality of these safety components. A well-chosen automatic door motor contributes significantly to the overall safety profile of a building.

Ensuring ADA Compliance and Accessibility

Ensuring ADA compliance and accessibility is not merely a legal obligation; it reflects a commitment to inclusivity. Commercial doors must provide easy access for all individuals, including those with disabilities. The Americans with Disabilities Act (ADA) sets specific guidelines for automatic door operation, focusing on aspects like opening force, closing speed, and clear opening widths. For example, Section 404.2.8 of the 2010 ADA Standards mandates that door closers must adjust so a door, when opened to 90 degrees, takes a minimum of 5 seconds to move to a position of 12 degrees from the latch. Similarly, for spring hinges, accessibility standards require that from an open position of 70 degrees, the door or gate must move to the closed position in a minimum of 1.5 seconds. Selecting an actuator that inherently meets these specifications simplifies installation and ensures continuous compliance, providing a welcoming and accessible entrance for everyone.

Choosing Appropriate Activation Methods

Selecting the right activation method significantly impacts user experience and operational efficiency. Various technologies exist, each suited for different commercial environments. Push buttons offer a simple, direct interaction, often found in offices or restrooms. Motion sensors provide hands-free activation, ideal for high-traffic areas like retail entrances, promoting hygiene and convenience. Touchless sensors, such as wave-to-open devices, further enhance hygiene, making them popular in healthcare facilities. Remote controls offer convenience for staff, allowing them to manage door access from a distance. Keypads or card readers integrate with access control systems, restricting entry to authorized personnel. The choice depends on the desired level of security, user convenience, and the specific needs of the building’s occupants.

Evaluating Environmental Conditions and Durability

Environmental conditions play a crucial role in determining the longevity and performance of automatic door motors. Exposure to extreme temperatures, moisture, dust, or corrosive agents demands specific material and protection considerations. For harsh outdoor environments, corrosion-resistant metal housings are recommended for connectors. High-temperature resistant plastic composites offer lightweight and flexible alternatives.

VULCON™ M-series connectors, suitable for harsh environments including automated doors & ramps, are rated to IP67/IP68.

An IP65 protection rating is advisable for electric motor units, especially those with integrated electronics. This rating ensures complete airtightness and very satisfactory watertightness. It prevents risks like fire from water seepage or dust damage. Such protection guarantees equipment can be safely left outdoors in an industrial setting. Durability also involves the quality of internal components and the motor’s ability to withstand continuous operation without premature wear. Investing in robust, environmentally appropriate Automatic Door Motors reduces maintenance costs and ensures reliable long-term performance.

Integrating with Security Systems

Integrating automatic door motors with security systems enhances both access control and emergency response capabilities. This integration allows for seamless operation, managing who enters and exits a building.

Automatic door motors integrate with access control systems through a defined sequence of operations:

- An employee or tenant presents an access credential (e.g., a proximity card or smartphone credential) to a door reader. This reader connects to an Access Control Unit (ACU).

- Once the ACU validates the credential, it sends a signal to the automatic door opener. This signal unlocks the door locking device, typically an electric strike or an electromagnetic lock.

- After the door locking device unlocks, the automatic door opener proceeds to open the door. It then closes the door after a predetermined time period, usually 5-10 seconds.

An automatic door opener is an electric-powered device. It opens or closes a door upon receiving a signal from an access control system. After an authorized access credential is presented, the door automatically opens. It stays open for a predetermined time (usually 5-10 seconds), and then closes. For exiting, a touch-less egress button can automatically open the door. These openers also include a built-in safety feature. They detect obstructions, stopping operation to prevent injury.

Key considerations for integrating automatic door motors with access control systems include:

- Expert Coordination: The project requires coordinated effort from a locksmith, electrician, and access control system provider. The access control provider often manages the project.

- Space Requirements: At least six inches of space between the ceiling and the door frame is needed for mounting the door opener. Alternative options exist if space is insufficient.

- Sizing: The automatic door opener must be appropriately sized for the door’s width.

- Electrical Requirements: Automatic door openers typically need a 120VAC direct power source. An electrician must wire this, ideally with wires hidden within walls and door frames.

Integration with fire alarm systems is equally critical. In an emergency, the system can automatically unlock doors or hold them open. This facilitates safe evacuation. This ensures compliance with fire safety regulations and protects occupants.

Considering Load Capacity, Stroke, Speed, and Force

Selecting an actuator requires careful consideration of several mechanical specifications. These include load capacity, stroke, speed, and force. Each factor directly influences the actuator’s suitability for a specific door application.

Load capacity refers to the maximum weight an actuator can effectively move. A heavy commercial door, such as one made of solid wood or metal, demands an actuator with a high load capacity. Insufficient capacity leads to premature wear and potential operational failure. Conversely, an oversized actuator for a lighter door represents an unnecessary expense.

Stroke defines the distance the actuator moves the door. For a sliding door, stroke corresponds to the full opening width. For a swing door, it relates to the angle of opening. The actuator’s stroke must match the door’s required travel distance. This ensures the door opens fully and closes completely.

Speed dictates how quickly the door opens and closes. High-traffic areas often require faster speeds to maintain efficient flow. However, safety regulations, particularly for low-energy operators, impose limits on door speed to prevent accidents. Balancing speed with safety and efficiency is crucial.

Force represents the power the actuator applies to move the door. It directly relates to the door’s weight and any resistance it encounters, such as wind pressure. An actuator must generate sufficient force to overcome these resistances. This ensures smooth and reliable operation under various conditions. Understanding these technical parameters helps specify an actuator that performs optimally and lasts longer.

Analyzing Budget and Return on Investment

Analyzing the budget and potential return on investment (ROI) is a critical step in selecting commercial door actuators. The initial purchase price varies significantly based on the type and features of the automatic door motor.

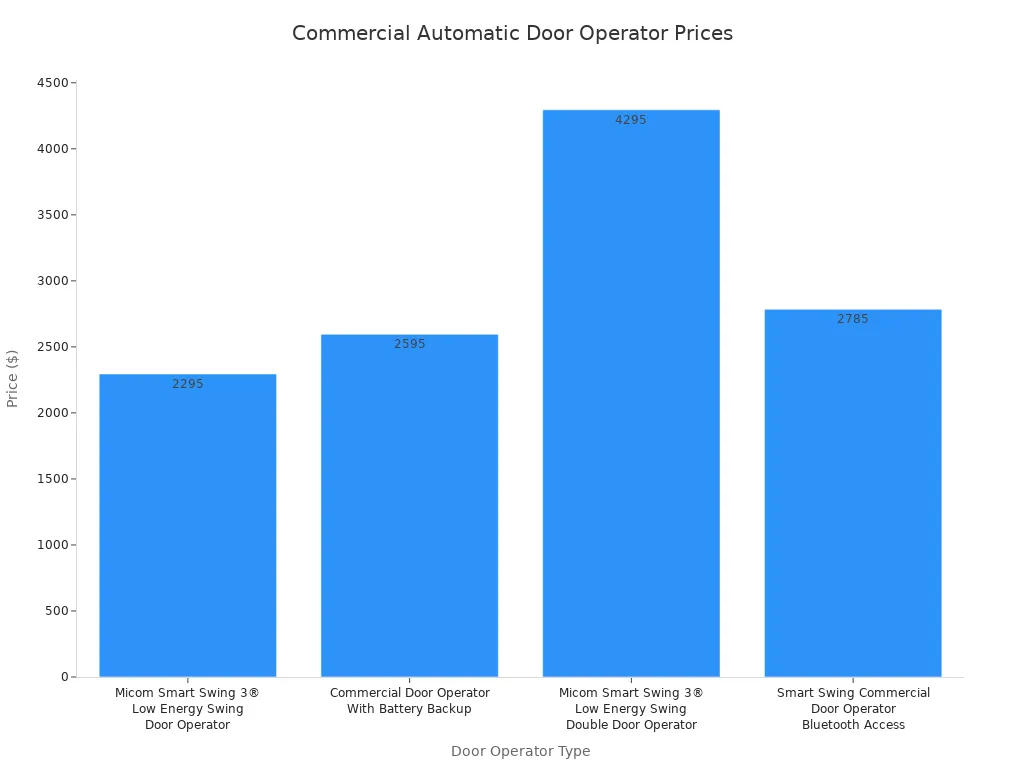

For instance, swing door openers typically range from $350 to $715. More advanced options, like the DC7000 Low Energy ADA Compliant Swing Door Operator, can cost between $1,190.48 and $2,380.95, depending on its configuration. Sliding door openers generally fall into a higher price bracket, from $2,000 to $10,000. Specialized commercial operators also show a range of prices:

| Commercial Automatic Door Operator | Price |

|---|---|

| Micom Smart Swing 3® Low Energy Swing Door Operator | $2,295.00 |

| Commercial Door Operator With Battery Backup | $2,595.00 |

| Micom Smart Swing 3® Low Energy Swing Double Door Operator | $4,295.00 |

| Smart Swing Commercial Door Operator Bluetooth Access | $2,785.00 |

The following chart illustrates the price variations across different commercial automatic door operators:

However, the total cost of ownership extends beyond the initial purchase. Several factors contribute to the overall expense:

- Installation Costs: This includes the door and its hardware, often accounting for half the expense. Labor typically makes up 30-40% of the total project cost. Permits can range from $50 to over $500. Hidden costs also arise, such as disposal of old doors, structural modifications, specialized equipment like lifts or cranes, and system integration with security or fire alarms.

- Maintenance Requirements: Automatic door systems require ongoing upkeep and repairs. Regular servicing ensures proper function and extends the lifespan of the equipment.

- Energy Consumption: The operational energy usage of the automatic door system contributes to recurring costs. Efficient models can offer long-term savings.

Businesses must consider these ongoing expenses when evaluating an investment. A higher initial cost for a more durable or energy-efficient automatic door motor can lead to significant savings over its operational life. This results in a favorable return on investment through reduced maintenance, lower energy bills, and enhanced operational efficiency.

Making the Right Choice: A Comprehensive Approach to Automatic Door Motors

Holistic Assessment of Operational Needs

A comprehensive assessment of operational needs forms the foundation for selecting the ideal automatic door motor. For high-traffic commercial areas like retail stores, robust and durable systems are essential for continuous operation. The chosen opener must accommodate the door’s weight and size, for example, 100-200 kg for standard glass doors, to ensure optimal function and prevent wear. Essential safety and control features include infrared/microwave sensors, anti-pinch protection, emergency stops, and smooth start/stop mechanisms. Integration with access control systems, such as card readers or biometrics, is also crucial. Energy efficiency and smart technology, like intelligent sensors that minimize opening times and reduce heating/cooling losses, are increasingly important. Furthermore, a quiet atmosphere is desired in retail spaces, making noise level and smoothness of operation critical considerations. Innovative technology integration and remote access allow for convenient monitoring and control.

Importance of Regulatory Compliance

Prioritizing regulatory compliance is non-negotiable for commercial door installations. The Americans with Disabilities Act (ADA) establishes comprehensive guidelines for automatic doors, ensuring accessibility for individuals with disabilities. Local and state building codes often incorporate additional requirements covering fire safety, emergency egress, and energy efficiency. International standards, such as ISO 16333, provide a global framework for automatic door safety and performance. North American standards like ANSI/BHMA A156.10 and A156.19 outline performance criteria for opening speed, sensor sensitivity, and safety mechanisms. Non-compliance with these regulations can lead to significant liabilities for property owners or managers, including legal action, fines, mandatory retrofitting, and reputational damage. It also hinders the independence and inclusivity of spaces.

Consulting Experts for Complex Installations

Consulting experts is highly advisable for complex automatic door installations. These professionals possess installation and maintenance expertise across various automated door systems, including electronic, electro-mechanical, and pneumatic types. They are knowledgeable in installing and maintaining door systems to meet life safety, fire, and ADA requirements. Experts can inspect and repair Life Safety Fire Door systems for regulatory compliance. They also have the technical skills to troubleshoot, repair, and maintain automated door systems, perform metal stud framing, and install low voltage electronic wiring. AAADM certification is essential for technicians, ensuring they possess the necessary skills and knowledge for safe and efficient handling of automatic door systems. Certified professionals understand complex door workings, ensuring correct installation and maintenance to minimize safety risks.

Selecting the ideal automatic door motor requires a thorough evaluation. This ensures optimal performance. Businesses must balance accessibility, efficiency, and safety in their choices. The right actuator provides smooth operation and user protection. For complex installations or specific needs, professional consultation offers tailored solutions. Experts guide the selection process effectively.

FAQ

What distinguishes full-energy from low-energy actuators?

Full-energy actuators operate doors quickly with high force for busy areas. They require strict safety measures. Low-energy actuators move doors slowly with less force. They prioritize user safety in controlled environments.

Why does ADA compliance matter for commercial doors?

ADA compliance ensures accessibility for all individuals, including those with disabilities. It mandates specific door operation guidelines. Meeting these standards avoids legal issues and promotes inclusivity.

How do environmental factors influence actuator choice?

Environmental conditions like temperature, moisture, and dust impact actuator durability. Harsh environments require corrosion-resistant materials and higher IP ratings. This ensures reliable long-term performance.

How do security systems integrate with automatic door motors?

Automatic door motors integrate with access control systems. They unlock doors upon credential validation. This manages entry and exit. Integration with fire alarms also facilitates emergency evacuation.

What is the typical lifespan of a commercial automatic door motor?

Commercial automatic door motors typically last 10 to 15 years. High-traffic usage can reduce this lifespan. Regular maintenance helps extend the motor’s operational life.

Tip: Consider the motor’s duty cycle and expected traffic volume when estimating its lifespan.