Selecting the ideal Automatic Door Motor for specific needs is crucial. People ensure the motor choice aligns with both performance and safety requirements. This helps people make an informed decision for long-term satisfaction. For instance, understanding "How to improve safety and efficiency of automatic door motors" is key. A good example is the YF200 Automatic Door Motor, known for its reliability. People also need to consider "How to choose an automatic door motor for sliding doors" and be aware of "Common automatic door motor problems and solutions." Sometimes, people even ask, "How to Know When Your Automatic Door Motor Needs Replacement?"

Key Takeaways

- Match the motor to your door type. Residential doors need quiet, safe motors. Commercial doors need strong, durable motors for heavy use.

- Check the motor’s power and size. The motor must be strong enough for your door’s weight and how often it opens.

- Look for safety features. Obstacle detection, emergency stops, and manual overrides keep people safe.

- Consider the motor’s lifespan and care. Good materials and regular maintenance make the motor last longer.

- Think about cost and setup. Compare the price of the motor and installation. Also, consider how much energy it will use over time.

Identify Your Door Type and Application for an Automatic Door Motor

Choosing the right motor starts with understanding the door itself. Different doors have different needs. Thinking about where the door is and what it does helps people pick the best motor.

Residential Door Motor Needs

Homeowners often look for convenience, quiet operation, and, most importantly, safety for their residential doors. These doors might include garage doors, sliding patio doors, or even automatic entry gates. For smaller or residential automatic doors, people often use single-phase induction motors.

When considering power, here is a general idea of what residential motors need:

| Motor Type | Power Range |

|---|---|

| Sheet Roller Doors | 300W – 400W |

| Tube Motors | 250W – 350W |

| Lightweight Doors | 250W – 300W |

| Medium Weight Doors | 350W – 400W |

| Smaller/Lighter Doors | 300W – 350W |

Safety features are also very important for homes. Residential openers should stop if they encounter resistance to prevent injury. For sliding doors, an auto-reverse on obstacle is standard. This causes the door to reopen if it hits something. Swinging doors, being low-energy, should also stop if obstructed.

Here are some common safety features people look for:

- Garage Door Sensors: These devices use an infrared beam. If something breaks the beam while the door closes, the opener stops and reverses. These sensors are legally required in the United States for all garage doors made since 1993.

- Auto-Reverse Mechanism: This is a backup safety measure. If sensors fail, it senses resistance when the door touches an object during closing. It then automatically reverses direction.

- Manual Release Mechanism: A red handle identifies this feature. It allows people to operate the door by hand during power outages or system failures. It works by disconnecting the door from the automatic opener.

- Battery Backup Systems: These systems keep the garage door working during power outages. They provide continued convenience and security.

- Manual Operation: Systems must allow people to use the door by hand. This means either pushing it open without triggering the motor or using a quick-release mechanism. This is vital for emergencies and when the power goes out.

Commercial Door Motor Requirements

Commercial doors face much higher traffic than residential ones. They need to be durable, reliable, and often more secure. These doors are in places like storefronts, office buildings, and warehouses.

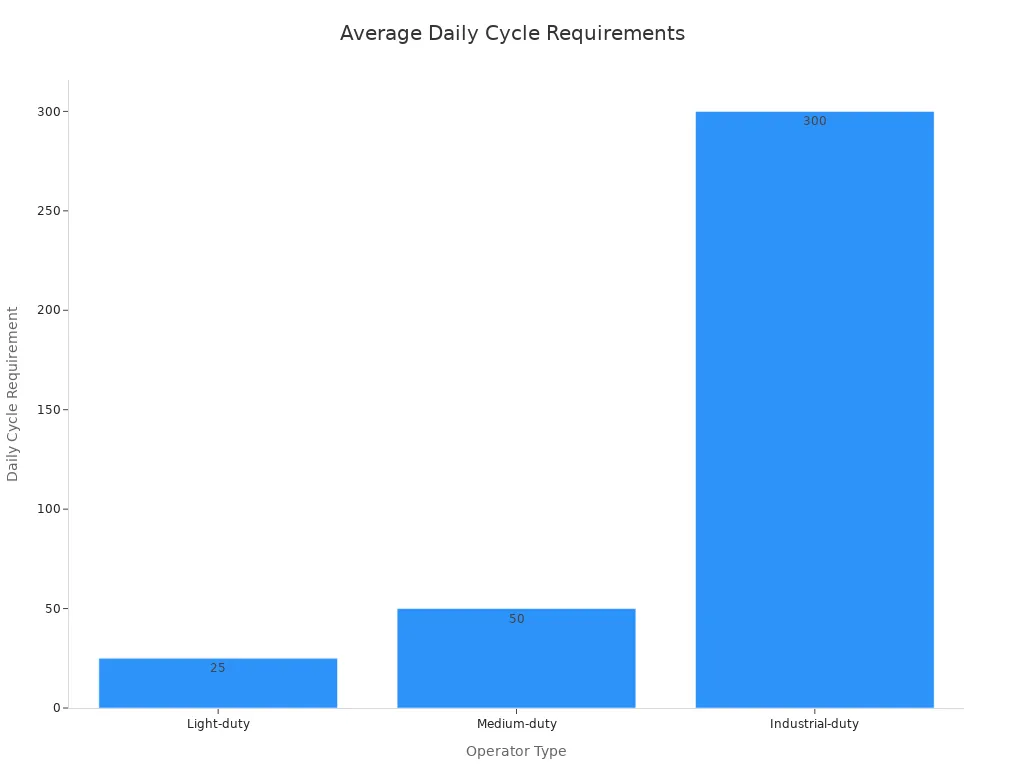

Commercial motors need to handle many cycles each day. Here is a look at average daily cycle requirements:

| Operator Type | Daily Cycle Requirement |

|---|---|

| Light-duty | 25 cycles |

| Medium-duty | 50 cycles |

| Industrial-duty | 300 cycles |

For example, a medium-duty jackshaft operator is rated for less than 50 cycles per day. It has a maximum of 12 cycles per hour. This makes it good for smaller, lighter commercial doors with mid-range daily use.

Commercial doors also need strong security and operational features. Here are some common ones:

- Secure Remote Control: This often includes a built-in radio receiver. It works with many remotes for secure open, close, and stop operations.

- Maintenance Alert System™: This system sets up maintenance schedules based on how many times the door opens or specific dates. It also has a self-diagnostic system to help fix problems.

- Timer-to-Close: People can program this to close the door automatically after it fully opens. This feature usually needs monitored photo sensors.

- Thermal Motor Overload Protection: People can easily reset this from the control station on the floor.

- Switchless Motor: This design improves reliability. It avoids common problems linked to start switches in single-phase operators.

- Diagnostic LEDs: These lights make installation and troubleshooting faster.

- Primary Monitored Entrapment Protection: This constantly checks safety devices to ensure safe operation. It limits door function if it detects an obstruction or if a device fails.

- Friction Clutch: This adjustable part helps prevent major damage to the door and operator if it hits something.

- Brake System: Solenoid-activated brakes are standard on some units. They stop the door from coasting.

- PosiLock® Mechanical Brake System: This is a self-locking mechanical system. It works as a holding brake.

Industrial Door Motor Considerations

Industrial doors are often very large and heavy. They operate in demanding environments like factories, warehouses, and distribution centers. These motors need to be extremely durable and handle continuous, heavy-duty cycles.

Industrial Automatic Door Motor specifications often include very high cycle ratings:

- Manaras Model OGH-6112: This motor is designed for 25 cycles per hour or 180 cycles per day.

- Nice PRO-GH: This is an industrial continuous duty motor.

- Nice PRO-H: This motor is for commercial/industrial continuous duty.

- Cornell SGH Motor Operator: This is for continuous, higher cycle use, exceeding 20 cycles per day.

- EuroDrive & Apex Pro SmartController™: These are rated for 1,000,000 cycles or 5 years.

- LiftMaster H and RBH: These are industrial duty, handling more than 12 cycles per hour, up to 80 cycles per day.

- LiftMaster GH and J: These are heavy industrial duty, designed for very high cycles, with the J model handling up to 80-90 cycles per day.

Environmental conditions are also a big factor for industrial motors. They often need protection from dust, moisture, and extreme temperatures.

- IP65-rated sealing against dust and moisture is a common environmental resistance rating.

- Some applications even use IP66-sealed hoist systems for even better protection.

- IP-rated housings protect against dust and moisture in outdoor installations.

Sliding Door Motor Specifics

Sliding doors have their own set of needs when it comes to motors. These doors move horizontally, often along a track. People typically find them in entrances to stores, offices, or even homes. The motor for a sliding door must provide smooth, quiet operation. It also needs to handle the door’s weight and size efficiently.

Consider the door’s weight and how often it opens. A heavier door needs a more powerful motor. A door that opens many times a day, like in a busy supermarket, requires a heavy-duty motor built for continuous use. For residential sliding doors, people often prioritize quiet operation and a compact motor design that blends with the door frame. Commercial settings, however, focus more on speed and durability.

Safety features are also very important for sliding doors. Anti-pinch technology prevents the door from closing on someone or something. Obstacle detection systems use sensors to stop or reverse the door if they sense an obstruction in its path. These features protect people and prevent damage to the door or motor.

Swing Door Motor Options

Swing doors open and close like traditional hinged doors. They pivot on an axis. Choosing the right motor for a swing door involves looking at several factors. These include the door’s size, weight, and how often it opens.

For swing door motors, the length of the door is a critical consideration. Even a lightweight door, if long, can put significant stress on the motor. This is especially true in windy conditions. For instance, a 16-foot aluminum door, even though it is light, needs a motor rated for longer doors. This prevents torque issues. Conversely, a short but very heavy door needs a motor with a high weight capacity. The best approach is to balance both factors. People should prioritize maximum door length in the motor specifications for long but light doors. They should focus on weight capacity for short but heavy doors. Always select a motor that can comfortably handle both dimensions without being pushed to its limits. The length of your door panels is a key factor in selecting the appropriate motor. Longer doors demand more force for smooth operation. Motors are designed to match specific door lengths, so ensure the chosen motor is compatible with your door’s length.

People commonly use two main types of swing gate openers:

- Crank-Arm Swing Gate Openers: These motors mount on the door frame or post. One end of the crank arm connects to the motor, and the other connects to the door leaf. The door moves as the arm expands, contracts, or rotates. They offer flexible installation and smooth operation. However, they require precise installation of the connection angle and have higher upkeep costs.

- Push-Rod Swing Gate Openers: These drive the door leaf by expanding and contracting a motor-powered push rod. Installers typically place them on the door frame or above the door leaf. They are easy to set up and widely compatible. But they have limited thrust for very heavy doors. They also have a restricted maximum opening angle, usually up to 105 degrees. This is a direct arm length consideration.

Here is a quick guide for recommended motor capacities:

| Door Type | Max Width | Max Weight | Recommended Motor Capacity | Torque |

|---|---|---|---|---|

| Residential Swing Doors | 12 feet | 300 pounds | 12V DC | 1000 Nm |

| Commercial Swing Doors | 20 feet | 800 pounds | 24V DC | 2000 Nm |

When choosing an Automatic Door Motor for a swing door, consider these specifications. They help ensure the motor performs well and lasts a long time.

Evaluate Key Specifications for Your Automatic Door Motor

After identifying the door type, people need to look closely at the motor’s technical specifications. These details ensure the motor can handle the door’s demands and operate efficiently.

Door Size and Weight Capacity for the Automatic Door Motor

The size and weight of a door are perhaps the most critical factors when choosing an automatic door motor. A motor must have enough power to move the door safely and reliably. People often find that openers are rated for specific dimensions and weights. The chosen opener must easily handle the door’s characteristics.

For example, a wall-mount unit for a Signature Series 2 HP Premium Screw Drive Garage Door Opener can handle a maximum door weight of 850 lbs for sectional doors. For swing doors, a model like the SW100 opener manages a door weight of 220.46 lbs.

Industrial doors often require much higher capacities. Here is a look at some maximum load capacities for industrial heavy-duty automatic sliding door motors:

| Motor Type | Maximum Load (kg) |

|---|---|

| Industrial Heavy Duty Automatic Sliding Door Motor | 1300 |

| Industrial Heavy Duty Automatic Sliding Door Motor | 800 |

| Industrial Heavy Duty Automatic Sliding Door Motor | 1200 |

| Industrial Heavy Duty Automatic Sliding Door Motor | 500 |

For sliding doors, the configuration also matters. A single door leaf might handle up to 200 kg, while double door leaves can manage 160 kg per leaf.

Torque is another important consideration, especially for specialized applications. For automatic chicken coop doors, a motor needs a high torque of at least 2 inch-pounds of force. This motor should operate with 6 to 24 volts DC and consume less than 600 milliamps, with approximately 100 RPMs. Chicken door opening sizes vary:

- Small Chicken Door: 8" x 8" Opening

- Automatic Chicken Door: 10"x10" Opening

- Large Automatic Coop Door: 12"x12" Opening

- Automatic Turkey Coop Door: 15"x15" Opening

- Certified Humane Automatic Coop Door: 21"x18" Opening

Commercial door operators do not always provide specific torque requirements. However, they indicate maximum door sizes. For example, some models handle up to 256 sq. ft., while others manage up to 168 sq. ft.

Power Supply and Energy Efficiency of the Automatic Door Motor

The power supply and energy efficiency of an automatic door motor directly impact operating costs and environmental footprint. People often find a dramatic difference in power consumption between older chain-drive garage door openers and newer belt-drive models with DC motors. This shows improved energy efficiency in modern designs.

Older automatic door models commonly feature AC motors. These generally consume more power. Newer models, however, often use DC motors, which are more energy-efficient. Modern DC motors can use up to 30% less energy than traditional AC motors. This leads to substantial operational cost savings over time.

Energy-efficient motors offer many benefits:

- Ease of Installation and Maintenance: Electric automatic doors require minimal additional components. This makes them easier to install and less complex to maintain.

- Energy Efficiency: They are more energy-efficient than hydraulic or pneumatic doors. They do not require separate pumps or compressors, resulting in lower energy costs over time.

- Versatility in Design and Functionality: Electric motors are easily programmable. They control speed and motion, allowing for customized opening and closing sequences. This suits different traffic types and special needs.

Brushless DC (BLDC) automatic door motors offer even more advantages:

- Long-Term Cost Savings: BLDC motors provide significant long-term cost savings through reduced operational expenses. A case study showed a 40% reduction in annual maintenance budgets over five years. Payback periods typically range from 12-18 months for high-utilization applications. Energy savings and reduced maintenance achieve this.

- Enhanced User Experience: These motors offer hands-free entry and exit, benefiting individuals with mobility challenges. Adjustable speed settings allow customization for user needs, and safety sensors prevent injuries. Quiet operation (low noise and vibration) creates a calm atmosphere. This is crucial for residential, smart home, and office buildings.

- Extended Operational Lifespan: The absence of brushes and commutators removes the primary source of mechanical wear and tear. This design results in a significantly longer service life. BLDC motors can reach up to 3 million cycles or approximately 10 years of consistent performance.

- High Torque and Energy Efficiency: These motors deliver high torque and excellent energy efficiency. They use worm and helical gear transmissions for smooth power transfer. This allows them to handle heavy sliding doors without performance loss and helps save energy, lowering operating costs.

- Ultra-Quiet and Low Vibration Operation: Operating at 50 decibels or less, these motors are similar to a quiet conversation. Brushless DC technology, automatic lubrication, and helical gear transmission contribute to smooth, quiet operation. This is ideal for noise-sensitive environments like hospitals and hotels.

- Durable, Maintenance-Free Construction: They are built with a fully sealed structure to prevent dust and oil leaks. They are also made from high-strength alloy materials. The brushless design eliminates the need for brush replacement, and the sealed gearbox is lubricated for life. This ensures long-term reliability with minimal servicing.

Opening Speed and Duty Cycle of the Automatic Door Motor

Opening speed and duty cycle are crucial for determining how quickly a door operates and how often it can open and close without wearing out. The duty cycle rating tells people how often a garage door can operate without premature wear.

Residential doors typically cycle 2-6 times daily, which is around 1,500 cycles annually. Commercial doors, however, can cycle 50-300 times daily. This difference requires robust commercial operators with continuous-duty motors. These motors are designed to run cooler and longer under high-intensity use. For instance, a commercial system rated for 25,000 cycles might reach that limit in 18 months at a busy facility. A residential system would take 15 years under normal home use. Installing residential-grade doors in commercial applications often results in repeated failures and costly downtime within the first year. This happens because of inadequate duty cycle capacity.

The frequency of garage door use significantly affects the opener’s lifespan. If a household opens and closes the garage more than 10 times a day, it places above-average stress on the motor, chain, and safety sensors. In such cases, upgrading to a smart opener with usage tracking helps monitor wear patterns. This also facilitates timely maintenance to prevent breakdowns.

Here is a comparison of residential and commercial system specifications:

| Specification | Residential Systems | Commercial Systems |

|---|---|---|

| Daily Use Frequency | 2-6 times per day | 50+ times per day |

| Annual Cycle Rating | ~1,500 cycles | 25,000-100,000 cycles |

| Cycles Per Hour | Not applicable | 30-300 cycles/hour |

| Expected Lifespan | 10-15 years | 10-15 years (with maintenance) |

| Motor Design | Standard | Continuous-duty, runs cooler, longer, overload protection, high starting torque |

Automatic gate motors generally last 10 to 15 years with normal usage and maintenance. Residential gates, used a few times daily, can last closer to 15 years. Commercial gates, opening and closing dozens of times daily, may have a shorter lifespan, around 7 to 10 years. A higher frequency of use (more open/close cycles) increases motor wear. For example, a small business gate used 40+ times daily (over 14,000 cycles annually) will wear down faster than a residential gate used 4-6 times daily.

Environmental Conditions for the Automatic Door Motor

The environment where people install an automatic door motor significantly impacts its performance and lifespan. Factors like temperature, humidity, and exposure to dust or water can challenge even the most robust systems. People must consider these conditions when choosing a motor to ensure it operates reliably for years.

Extreme temperatures greatly affect how an automatic door motor performs and how long it lasts. Temperature changes cause mechanical parts to expand and contract. This leads to wear and tear over time. For example, very hot weather can warp plastic parts, while severe cold can make metal components brittle. These conditions directly stop the opener from working correctly. Insulation solutions, such as insulating garage walls or using weather stripping, help reduce these problems by keeping the temperature more stable.

Here is how different temperatures affect garage door openers:

| Temperature Range | Effects on Garage Door Opener |

|---|---|

| Below 32°F | Increased brittleness of components |

| Above 90°F | Warping of parts |

Cold temperatures make batteries drain much faster or even freeze. This causes malfunctions, especially for systems that use batteries or solar power. Extreme heat can make the motor overheat. This might trigger thermal shut-offs or shorten its lifespan, especially if people use it often. High temperatures also make lubricants dry out faster. This increases friction between moving parts and causes premature wear if people do not reapply them often. Extreme heat also negatively affects battery efficiency and can make batteries overheat, shortening their overall life.

Different motor types handle temperature differently:

- Chain-drive openers are durable, but people need to lubricate them regularly in high temperatures to prevent wear.

- Belt-drive systems are less affected by temperature-related expansion or contraction. This makes them a good choice for hot places.

- Screw-drive openers need specific maintenance to handle the challenges of extreme heat effectively.

For outdoor installations, people need motors with proper protection against dust and moisture. This is where IP (Ingress Protection) ratings become important. These ratings show how well an enclosure protects against solids and liquids. For outdoor automatic door motors, people often recommend IP65, IP66, or higher ratings. An IP65 rating means the motor is dust-tight and can withstand low-pressure water jets from any direction. An IP66 rating offers even stronger protection against powerful water jets. For very demanding environments, like those needing high-temperature and high-pressure wash-downs, an IP69K rating ensures dust-tightness and the ability to withstand steam cleaning.

Prioritize Safety and Compliance for Your Automatic Door Motor

Safety is paramount when people choose an automatic door motor. People must ensure the system protects users and prevents accidents. This involves looking at obstacle detection, emergency controls, and industry standards.

Obstacle Detection Systems for the Automatic Door Motor

Modern automatic doors rely heavily on obstacle detection systems. These systems prevent the door from closing on people or objects. Many doors feature integrated obstacle detection with a reverse mode. This means the door automatically reverses direction if it encounters resistance. People can also connect additional external sensors for enhanced safety. These sensors provide a protective function. They trigger an immediate change of direction if an obstacle appears.

Advanced systems use intelligent AI motion sensors. These sensors offer touchless, high-sensitivity operation. They can distinguish between human figures and general movement. This enhances the anti-pinch function. It ensures the door reopens automatically if it detects an obstacle during closing.

However, even advanced sensors have limitations:

| Sensor | Limitations/Weaknesses |

|---|---|

| Ultrasonic Sensor | Limited range and narrow beam angle. Susceptible to environmental factors like temperature and humidity. |

| Infrared (IR) Sensor | Performance depends on ambient light and temperature. Limited range and field of view. |

| Camera (Vision Sensor) | Performance depends on lighting conditions. Computationally intensive for real-time processing. |

Emergency Stop and Manual Override for the Automatic Door Motor

Emergency stop and manual override features are critical for user safety. An emergency stop button immediately halts the door’s movement. This prevents injuries or damage in urgent situations. Manual override allows people to operate the door by hand. This is essential during power outages or system malfunctions. It ensures people can always open or close the door when needed.

Industry Safety Standards for the Automatic Door Motor

Manufacturers must meet specific industry safety standards. These standards ensure the Automatic Door Motor operates safely and reliably. Compliance protects users and guarantees product quality. People should always choose motors that adhere to relevant safety certifications. This provides peace of mind and ensures long-term safe operation.

Consider Durability, Maintenance, and Warranty of the Automatic Door Motor

People want their automatic door systems to last a long time. They also want them to work well without constant problems. Thinking about durability, maintenance, and the warranty helps people make a smart choice.

Motor Material and Build Quality

The materials used in a motor and how it is built greatly affect its strength and how long it lasts. High-quality motors often use strong metals and durable components. These materials resist wear and tear better. They also stand up to different weather conditions. A well-built motor means fewer breakdowns and a longer working life. People should look for motors with robust casings and internal parts designed for heavy use. This ensures the motor can handle its job day after day.

Expected Lifespan and Maintenance Needs

Every motor has an expected lifespan. Regular maintenance helps extend this life. Garage door openers typically last between 10 to 15 years. This lifespan depends on the opener’s quality, how often people use it, and how consistently they maintain it. High-quality openers and professional maintenance can help them last even longer.

Here is a general idea of how long different gate motors can last:

| Motor Type | Average Lifespan (Years) |

|---|---|

| Sliding Gate Motors | 10-15 (up to 20 with maintenance) |

| Swing Gate Motors | 10-15 |

| Barrier Gate Motors | 10-15 |

| Cantilever Gate Motors | 15-20 |

| Vertical Lift Gate Motors | ~15 |

| Bi-folding Gate Motors | 10-15 (with regular maintenance) |

| Telescopic Gate Motors | 10-15 |

Regular maintenance keeps the motor running smoothly. It also prevents small issues from becoming big problems. Here is a typical maintenance schedule:

- Daily: Perform a quick visual inspection and clean sensors.

- Monthly: Inspect for loose hardware and lubricate moving parts.

- Quarterly: Conduct a thorough inspection of all components. Check for wear and test safety features.

- Yearly: Engage a professional technician for a comprehensive system check, adjustments, and specialized repairs.

Manufacturer’s Warranty and Support

A good warranty gives people peace of mind. It shows the manufacturer stands behind their product. People should always check the warranty period and what it covers. A longer warranty often means the manufacturer trusts their motor’s durability. Good customer support from the manufacturer is also important. They can help with troubleshooting, parts, and service if problems arise. This support ensures people get help when they need it.

Determine Budget and Installation for Your Automatic Door Motor

When you choose an automatic door motor, you also need to think about money and how you will set it up. This includes the first costs and what you will pay over time.

Initial Purchase and Installation Costs

The cost of an automatic door motor and its installation can vary a lot. For example, a garage door opener, including installation, typically costs between $441 and $754. If you need professional installation for automatic door openers, you might pay $600 to $1,000 per opener. A basic swing door opener costs about $350 to $715 when installed, while an advanced one can be $500 to $1,000. Sliding door openers are usually more expensive. A basic one costs $2,000 to $4,000 installed, and an advanced one can be $4,000 to $10,000. Smart garage door openers often cost $395 to $600 installed.

Several things affect the total cost. The type of opener plays a big role. Chain drive openers, which use a metal chain, cost about $150 to $250. Belt drive openers use a belt and are quieter, costing $200 to $500. Screw drive openers have a rotating rod and are good for heavier doors, also costing $200 to $500. The door’s size also matters. Larger automatic sliding doors need stronger motors, which increases the price.

Long-Term Operating Costs

The initial price is not the only cost. You also need to think about how much money you will spend over time. The long-term energy costs for automatic door motors are usually not too high for most homes. However, they depend on the motor type, how often you use the door, and any extra features. You can greatly reduce these costs by picking efficient motors and doing regular maintenance. Using technologies like LED lighting also helps. Investing in modern, energy-saving doors with low-consumption motors can save you a lot on electricity bills and maintenance over time.

| Feature | Impact on Long-Term Energy Costs |

|---|---|

| Energy-Efficient Motors | They use less power, which lowers electricity bills. |

| Brushless DC Motors | They are very efficient and last longer, reducing replacement costs. |

| Smart Control Systems | They make the motor work best for current conditions, using only the power it needs. |

| Regular Maintenance | It keeps the system working well and saves energy by preventing problems. |

Professional Installation vs. DIY

You can choose to install an automatic door motor yourself or hire a professional. Doing it yourself can save money upfront, but it also carries risks. If you ignore the manufacturer’s instructions, you might set it up wrong and void your warranty. Skipping safety tests for sensors and auto-reverse features can lead to dangerous problems. Improper installation can create a hazardous situation. For example, if you do not install an opener reinforcement bracket, you could damage the door. Faulty wiring from poor installation can cause serious electrical dangers like power surges, shorts, or fires. This can damage the opener and your home’s electrical system.

Choosing the right automatic door motor involves several key considerations. People must assess door type, specific technical specifications, and crucial safety features. They also need to think about durability and maintenance. Balancing performance, safety, and budget ensures a successful choice. For complex installations, professional consultation is always recommended. This helps guarantee optimal functionality and long-term satisfaction.

FAQ

How often should people maintain an automatic door motor?

People should perform daily visual checks and monthly inspections. They need to lubricate moving parts. A professional technician should conduct a comprehensive system check yearly. This helps ensure long-term reliability and prevents major issues.

What is the difference between AC and DC motors for automatic doors?

AC motors are older and use more power. DC motors are newer and more energy-efficient. They can use up to 30% less energy. DC motors also offer smoother, quieter operation and often have a longer lifespan.

Can people install an automatic door motor themselves?

People can install some motors themselves. However, professional installation is often recommended. Incorrect installation can void warranties or create safety hazards. It can also lead to electrical dangers or damage to the door.

What safety features are most important for automatic door motors?

Obstacle detection systems are crucial. They reverse the door if they sense an object. Emergency stop buttons and manual override features are also vital. They allow people to stop the door or operate it by hand during power outages.

How do environmental conditions affect motor performance?

Extreme temperatures can cause parts to expand or contract. This leads to wear. Dust and moisture can damage internal components. People need motors with proper IP ratings for protection. This ensures reliable operation in harsh environments.