Selecting the ideal automatic door operator is a critical decision for any commercial building. A well-chosen system offers significant advantages, including enhanced accessibility for all users and improved security measures. It also promotes energy efficiency by maintaining indoor temperatures. Businesses seek the best automatic door operator for commercial use to ensure smooth operations and convenience. Ningbo Beifan Automatic Door Factory, a reputable Automatic Door Manufacturer, recognizes these diverse requirements. Understanding specific building needs is crucial, even before considering how to install automatic door operator systems effectively. This careful consideration ensures the operator matches your unique commercial environment.

Key Takeaways

- Understand your building’s needs first. Consider how many people use the door and who they are. This helps you pick the right automatic door operator.

- Check the door’s size and weight. Heavy doors need strong operators. Make sure the operator matches your door to work well and last long.

- Prioritize safety and energy saving. Look for operators with good safety features and those that save energy. This protects people and lowers your bills.

- Choose the right type of door system. Sliding, swing, revolving, or folding doors each work best for different spaces. Pick one that fits your building’s layout.

- Think about how the door will open. You can use motion sensors or push buttons. Pick a system that is easy for everyone to use and keeps your building secure.

Assessing Commercial Building Needs for an Automatic Door Operator

Traffic Volume and User Demographics

Understanding a commercial building’s traffic volume and user demographics is the first step in selecting an appropriate automatic door operator. Buildings with high foot traffic, such as retail stores, airports, or hospitals, require robust and durable operators. These environments demand doors that can handle frequent cycles without failure. Conversely, buildings with lower traffic, like small offices or private clinics, might prioritize quiet operation or specific aesthetic features over sheer endurance.

User demographics also play a significant role. Facilities serving a diverse population, including children, the elderly, or individuals with disabilities, need doors that operate smoothly and safely. For example, a children’s hospital might require slower closing speeds and enhanced safety sensors. An assisted living facility would benefit from doors with extended hold-open times. Considering these user groups ensures the automatic door system provides convenience and safety for everyone.

Operational Speed and Accessibility Requirements

Operational speed directly impacts efficiency and user experience. In busy commercial settings, a fast-opening and closing door helps maintain traffic flow and reduces energy loss. However, speed must balance with safety and accessibility. An automatic door operator must not close too quickly, potentially endangering users.

Compliance with ADA guidelines is crucial for accessibility. These guidelines state that when automatic doors are provided, they must comply with industry standards. These standards cover operating characteristics like opening speed, safety features, sensors, activation devices, and labeling.

- Power-Assisted Doors: These devices reduce the force needed to open a door. They must meet specific maneuvering clearance requirements.

- Controls: Door and gate controls must be operable with one hand. They should not require tight grasping, pinching, or twisting of the wrist. The force needed must not exceed 5 lbf. A clear floor space at controls must be located outside the door swing. This prevents users from being hit.

- Placement of Sensors or Push-Buttons: If a push-button activates the door, a level clear floor space must be provided at the button. The button should be placed conveniently along the approach to the door. The door must not swing into this clear floor space.

- Timing of Door Closing: The hold-open time may need to increase. This depends on the distance of the push-button from the door. This allows sufficient entry time, as regulated by ANSI/BHMA A156.10.

- Maneuvering Clearances: Most requirements for automatic doors are found in ANSI/BHMA A156.10. This covers clearances, timing, and sensor/push-button locations. Power-assisted swinging doors always require normal accessible maneuvering clearances.

- Automatic Doors in New Construction: Doors serving accessible means of egress must have standby power. Alternatively, they must remain open in power-off conditions. They can also have the minimum accessible maneuvering clearances required for a manual door.

- Automatic Doors in Renovations: These doors can address slope or maneuvering clearance issues. Standby power is not required for these doors in existing buildings. Accessible means of egress are not mandated in alterations to existing buildings.

Meeting these accessibility requirements ensures the automatic door system serves all individuals effectively and legally.

Evaluating Door Characteristics for Automatic Door Operator Selection

Door Type, Size, and Weight

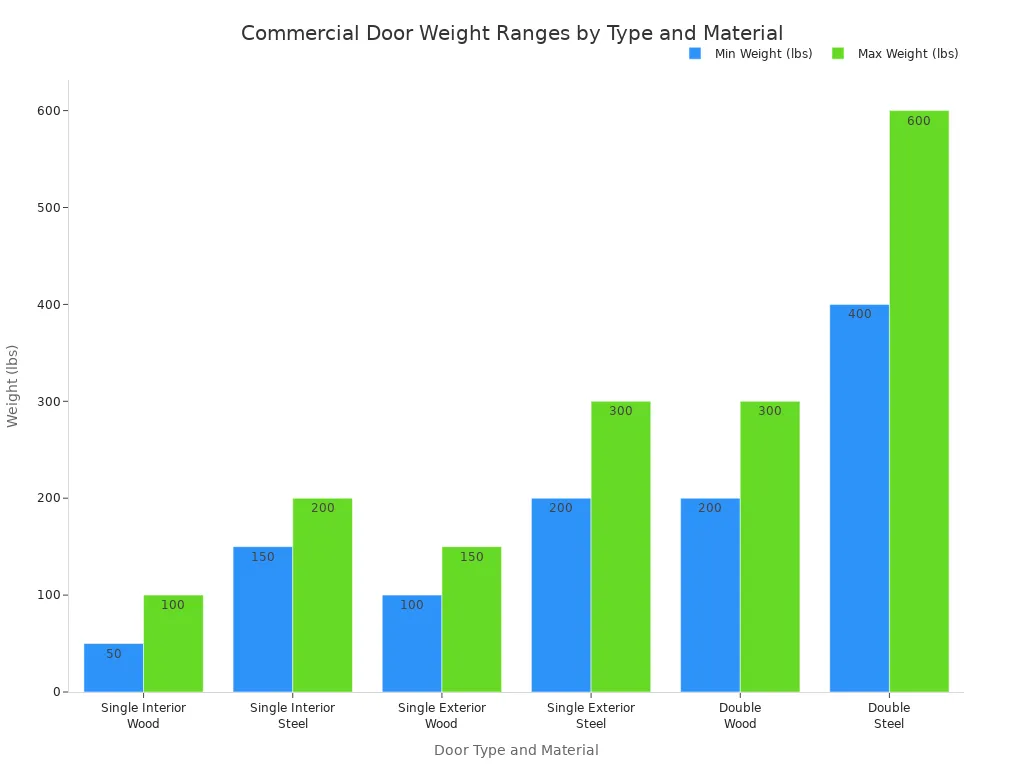

The physical characteristics of a door significantly influence the choice of an automatic door operator. Different door types, such as single or double, and their materials, like wood or steel, determine the door’s overall weight. A heavier door requires a more powerful operator to ensure smooth and reliable function. Selecting an operator with insufficient power can lead to premature wear and operational failures.

Consider the typical weight ranges for various commercial door types:

| Door Type (Fire-Rated) | Material | Weight Range (lbs) | Weight Range (kg) |

|---|---|---|---|

| Single Interior | Wood | 50 – 100 | 22.7 – 45.4 |

| Single Interior | Steel | 150 – 200 | 68 – 90.7 |

| Single Exterior | Wood | 100 – 150 | 45.4 – 68 |

| Single Exterior | Steel | 200 – 300 | 90.7 – 136 |

| Double | Wood | 200 – 300 | 90.7 – 136 |

| Double | Steel | 400 – 600 | 181.4 – 272.2 |

This data shows that steel doors are much heavier than wood doors. Double doors also weigh more than single doors. An automatic door operator must match the door’s weight for optimal performance and longevity.

Existing Infrastructure and Space Constraints

Existing infrastructure and space limitations present important considerations for automatic door operator installation. Logistical constraints often arise during the installation process. These constraints relate to the physical space around the doorway.

Specific standards address these space requirements:

- Clear Width (Standard 404.3.1): Doorways must offer a minimum clear opening of 32 inches (815 mm). This applies whether the power is on or off.

- Maneuvering Clearance (Standard 404.3.2): Doors need specific clear spaces. These spaces depend on the approach direction and door type. This ensures easy passage for all users.

- Thresholds (Standard 404.3.3): Door thresholds and level changes must meet specific height limits. New construction limits thresholds to 1/2 inch.

- Doors in Series (Standard 404.3.4): Doors installed one after another require maneuvering space for both. They also need at least 48 inches of space between them.

- Controls (Standard 404.3.5): Manual controls must be operable with one hand. They should not require tight grasping. The clear floor space near the control must be outside the door’s swing path.

- Break Out Opening (Standard 404.3.6): Doors without standby power, which are part of an exit route, must have a minimum 32-inch clear break-out opening in an emergency.

These standards ensure accessibility and safety. They directly impact the type and placement of an automatic door operator.

Prioritizing Key Performance Factors for Your Automatic Door Operator

Safety Compliance and Security

Safety and security are paramount for any commercial automatic door operator. A reliable system protects users and assets. The Federal Register outlines the primary safety standard for automatic residential garage door operators in PART 1211. This standard incorporates UL 325-2017. It focuses on evaluating circuits. Key requirements include robust entrapment protection features. These include inherent primary entrapment protection and secondary entrapment protection. Control accessories must not interfere with these safety features. Operators must also provide connections for external secondary entrapment protection devices.

Modern automatic door operator systems offer advanced security features. These include advanced sensors. They constantly scan for movement and presence. This ensures the door opens for approaching individuals. It also prevents closing if someone is still in the doorway. Anti-pinch protection detects obstructions. It immediately stops or reverses the door’s movement. Emergency battery backups allow doors to operate during power failures. Integration with access control systems ensures only authorized personnel can enter specific areas.

Energy Efficiency and Noise Levels

Energy efficiency helps reduce operating costs. An efficient automatic door operator minimizes heat loss or gain. This maintains indoor temperatures. It contributes to a building’s overall sustainability. Noise levels also impact the commercial environment. A quiet operator improves comfort for occupants and visitors. This is especially important in offices, hospitals, or retail spaces.

Different automatic door operator types have varying noise levels:

| Automatic Door Operator Type | Typical Noise Level (dB) |

|---|---|

| Sliding Auto Gate Motor | 50 – 55 |

| Smart Sliding Gate Opener | 45 – 50 |

| Heavy Duty Smart Gate Opener | 55 – 60 |

Lower decibel levels indicate quieter operation. This makes them suitable for environments where noise reduction is a priority.

Maintenance and Serviceability

Considering maintenance and serviceability ensures long-term reliability. A well-maintained automatic door operator lasts longer. Electro-mechanical models typically last 5-10 years. Pneumatic systems can last significantly longer. Regular maintenance prevents unexpected breakdowns.

Recommended maintenance schedules vary based on usage. Most garage doors need service every 12 months. Some require service at least twice a year. Frequent use demands quarterly maintenance. Extreme climate conditions also influence maintenance frequency. Servicing the door in the fall or spring prepares it for harsh temperatures. Easy access to components and readily available parts simplify repairs. This reduces downtime and operational disruptions.

Exploring Types of Automatic Door Operator Systems

Different commercial environments benefit from various automatic door operator systems. Each type offers unique advantages for specific needs. Understanding these differences helps in making the best selection.

Sliding Automatic Door Operators

Sliding automatic door operators move door panels horizontally along a track. These systems are very common in many commercial settings. They provide a wide, clear opening without needing extra space for the door to swing.

Sliding automatic door operators find use in many places:

- Hospitals: They help maintain cleanliness and allow quick, easy movement.

- Malls and Retail Stores: These doors make shopping more convenient. Shoppers do not need to open doors manually.

- Airports and Train Stations: They help manage large crowds. They prevent congestion at entrances.

- Hotels: These doors improve guest comfort. They create a welcoming arrival experience.

- Homes: They work well for tight spaces, modern designs, patio doors, or internal sliding panels.

- Offices: People use them in meeting rooms and main entrances.

These operators offer several benefits. They provide enhanced convenience and accessibility. They allow effortless entry and exit for all users. This improves access for individuals with disabilities or limited mobility. They remove the need for manual operation. They also give enough time for people to pass through. Modern operators also increase security. They feature anti-lift mechanisms and tamper-resistant parts. These include hidden bolts and strong steel. They can also have integrated alarm systems. These systems alert staff to unauthorized access and offer real-time monitoring.

High-efficiency sliding door operators also reduce energy costs over time. They use little power during operation and standby. This lowers electricity bills. Their design minimizes heat loss or gain. This helps keep indoor temperatures stable. It saves money on heating and cooling. These operators also have a longer lifespan. They use durable materials and precise engineering. This reduces wear and tear. It leads to fewer mechanical failures and less frequent maintenance. This results in a longer operational life. They also improve the look of a building. Modern operators have sleek designs. They often hide tracks and motors for a clean appearance. They come in various finishes to match decor. They operate smoothly and quietly, adding to a premium feel.

However, these advanced systems also have some drawbacks. High-efficiency operators cost more initially. They use premium materials and advanced technology. This means a significant upfront investment. They also have increased complexity. Advanced operators have intricate designs and functions. This makes installation more challenging. It often requires professional expertise. They also need regular maintenance. This may require a maintenance agreement with a technician. For infrequent use, an overly efficient system might offer features that people do not fully use. This leads to unnecessary expenses. Building owners should match the operator’s capabilities to their actual usage patterns. This avoids over-specification.

Swing Automatic Door Operators

Swing automatic door operators open and close doors like traditional hinged doors. They use a motor to push or pull the door open. These operators are versatile. They can convert existing manual swing doors into automatic ones. This makes them a popular choice for many buildings.

Swing automatic door operators are common in:

- Commercial buildings

- Educational facilities

- Healthcare settings (hospitals, care homes, cleanrooms)

- Leisure facilities (restaurants, hotels)

- Retail spaces

- Offices

- Corridors

- Libraries

These operators are good for places where space allows the door to swing freely. They offer reliable performance and accessibility.

Revolving and Folding Automatic Door Operators

Revolving and folding automatic door operators serve specialized purposes. Revolving doors rotate around a central axis. They create an airlock effect. This helps maintain indoor temperatures and reduces drafts. They are excellent for energy efficiency in high-traffic areas.

Revolving doors are often found in:

- Airports

- Hospitals

- Hotels

- Schools

- Restaurants

- Manufacturing Facilities

- Financial/Government institutions

- Shopping Malls and Retail stores

- Upscale Condominiums

- Call Centers

Folding automatic doors are ideal when space is limited. They provide a maximum door opening in tight areas. They offer convenience and accessibility in the smallest environments. They allow barrier-free, two-way traffic. They use only a fraction of the space that sliding or swing doors require. These systems work well for narrow corridors, retrofit projects, and new construction.

Common applications for folding automatic doors include:

- Corridor applications

- Vestibules

- Hospital corridors, especially where wide openings are needed in narrow spaces

These specialized operators provide solutions for unique architectural and functional requirements.

Activation and Control Systems

The way users activate an automatic door operator is crucial. Various activation and control systems exist. These include motion sensors, push buttons, and access control systems. Motion sensors detect approaching individuals. They open the door automatically. Push buttons require a user to press a button. Access control systems integrate with security. They only allow authorized entry. Remote controls and touchless sensors also offer convenience and hygiene benefits. Selecting the right activation system depends on traffic patterns, security needs, and user preferences.

Activation and Control Systems

The way people activate an automatic door operator is crucial. Various activation and control systems exist. These systems ensure the door opens and closes at the right time. They also manage the door’s overall operation.

Early automatic door systems used simple activation methods. Pressure-sensitive mats were common. These mats relied on electrical circuits, hydraulic pressure, or air compression tubing. They detected a person’s weight. Later, overhead sensors replaced these mats. These sensors used early infrared or microwave technologies. They detected movement from above the doorway.

Modern automatic door operators use more advanced sensors. These sensors ensure maximum accuracy and minimize false triggers. A door motion sensor is an automated detection device. It identifies motion near an entrance. It then triggers the door to open or close. These sensors often use infrared, microwave, or dual-technology detection. For example, the HR-Robus is a high-mount microwave motion sensor. It activates industrial, commercial, or pedestrian motion-activated doors. It detects vehicle or pedestrian motion on approach or departure. Installers can mount it as high as 23 feet.

Automatic door operators also differ in how they respond to activation.

- Low-Energy Operators: These require a ‘Knowing Act’. This means a person must consciously input a command. Common devices for this include:

- Push Buttons

- Touchless Switches

- Card Readers & Keypads

- Full-Energy Operators: These activate automatically. Motion sensors detect movement near the door. They then trigger the door to open.

Beyond activation, robust control systems manage the door’s functions. Automatic door operators often feature a microprocessor-based unit. This unit is self-tuning and self-learning. It offers various interface options. It connects with sensors, push-plates, fire alarms, and electrified locks. Door controllers and remote control consoles provide management for these operators. They allow staff to oversee and adjust door settings.

The underlying technology of the control system also varies.

- Electrohydraulic systems use hydraulic fluid to power the door.

- Electromechanical systems rely on electric motors and gears.

- Pneumatic systems use compressed air for operation.

Choosing the right activation and control system depends on several factors. These include traffic patterns, security needs, and user preferences. Remote controls and touchless sensors offer convenience and hygiene benefits. They provide a safe and efficient entry experience for everyone.

Selecting the right automatic door operator involves careful consideration. Businesses assess traffic, door characteristics, and performance factors. They also explore different operator types and control systems. A well-chosen system offers long-term benefits. These include enhanced safety, improved accessibility, and significant energy savings. It also reduces maintenance costs. For optimal results, professional consultation is highly recommended. Experts ensure the chosen solution perfectly matches specific commercial needs.

FAQ

What is the most important factor when choosing an automatic door operator?

The most important factor is understanding the building’s specific needs. This includes traffic volume, user demographics, and door characteristics. Matching the operator to these requirements ensures optimal performance and safety.

How do automatic door operators improve accessibility?

Automatic door operators provide effortless entry and exit for all users. They comply with ADA guidelines. These guidelines cover operating speeds, safety features, and clear maneuvering spaces. This ensures accessibility for individuals with disabilities.

Can an automatic door operator be installed on any type of door?

No, the door’s type, size, and weight are crucial. A heavier door requires a more powerful operator. Selecting an operator that matches the door’s physical characteristics prevents premature wear and ensures reliable function.

Do automatic door operators save energy?

Yes, high-efficiency automatic door operators reduce energy costs. They minimize heat loss or gain. This helps maintain stable indoor temperatures. This contributes to a building’s overall sustainability and lowers utility bills.

How often do automatic door operators need maintenance?

Maintenance frequency depends on usage. Most operators need service every 12 months. High-traffic doors or those in extreme climates may require quarterly maintenance. Regular checks prevent breakdowns and extend the operator’s lifespan.